Selection of production line equipment for crushing and processing granite

Crushing and processing granite is one of the important links in the ore processing industry. Granite is widely used in construction and road construction, urban gardening and decoration due to its hard characteristics and high density. In the process of crushing and processing granite, choosing appropriate production line equipment is crucial to improving production efficiency and product quality.

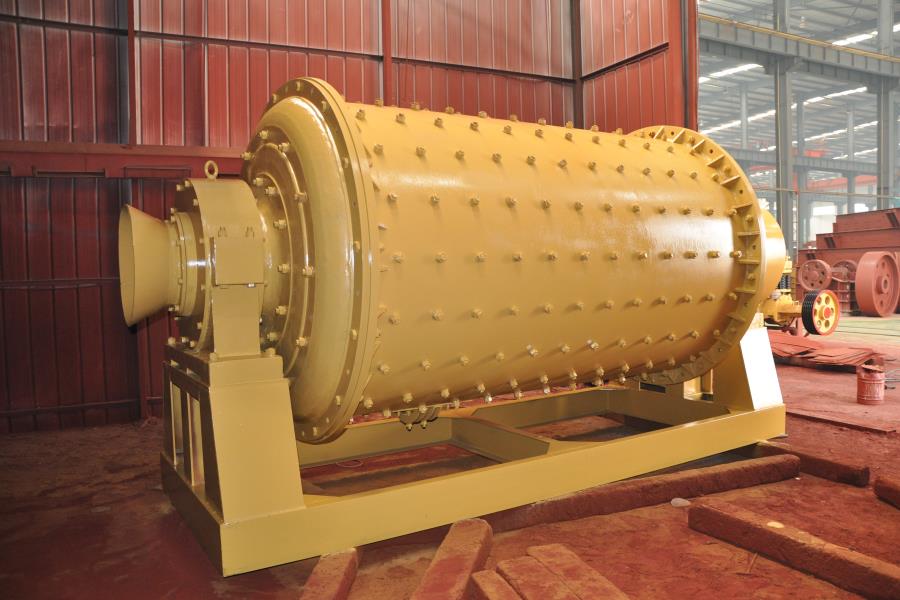

First of all, crushing equipment is one of the key equipment in the granite processing production line. Common crushing equipment includes jaw crusher, cone crusher and impact crusher. Jaw crusher is suitable for primary crushing, and its sturdy structure and high crushing ratio can effectively handle granite with higher hardness. Cone crusher is usually used for medium and fine particle size crushing. Its unique design and high crushing efficiency make it an ideal choice for granite crushing. Impact crusher is suitable for coarse, medium and fine crushing, and can produce three-dimensional particles, which is more suitable for use in the construction field.

For the screening and sorting of granite, in traditional production line equipment, vibrating feeder and vibrating screen are commonly used screening equipment. The vibrating feeder can evenly feed the raw materials into the crushing equipment for crushing, while the vibrating screen can grade and screen the crushed materials to ensure the yield and quality of the product.

For the washing of crushed granite blocks and aggregates, spiral sand washing machines and sand washing equipment are commonly used equipment. The spiral sand washing machine can effectively wash and remove impurities from granite aggregates to meet the material requirements of construction, cement concrete and other fields.

For the transportation and storage of the entire production line, belt conveyors and stackers are one of the indispensable equipment. The belt conveyor can transport the crushed granite blocks at high speed, while the stacker can store the raw materials in the designated site or warehouse to ensure the smooth operation of the production line.

When selecting equipment for the granite crushing and processing production line, factors such as the hardness of the raw materials, processing requirements, and production scale should be considered. Choosing appropriate equipment can improve production efficiency, reduce energy consumption, and ensure product quality, thereby achieving investment recovery and reducing production costs.

OCP Machinery Company has been focusing on the production and manufacturing of mining machinery and equipment for nearly 40 years. It has rich experience and mature technology. It can tailor-make exclusive production line equipment for you according to your actual production needs. In addition, it is a direct sales manufacturer with no middle links and more economical prices. Friends in need can click to consult for preferential quotes at any time. Customer service is online 24 hours a day.

-

How much is the output of a small mobile crusher and how much is the price

-

What types of mobile crushing equipment with an output of 200 tons per hour are there

-

Scheme configuration of mountain stone crushing and sand making production line

-

Causes and solutions for abnormal vibration of vertical shaft impact sand making machine