Scheme configuration of mountain stone crushing and sand making production line

With the continuous development of the construction industry, mountain stone crushing and sand making production line plays an important role in modern construction. The reasonable configuration of this production line is of great significance to improving production efficiency and reducing production costs. This article will introduce the scheme configuration of mountain stone crushing and sand making production line, in order to provide reference for professionals in related fields.

1. Demand analysis

When designing a mountain stone crushing and sand making production line, it is necessary to first conduct a demand analysis. Considering factors such as the type and scale of raw materials, the processing capacity of the production line, and the quality standards of the final product, the appropriate configuration scheme can be determined.

2. Raw stone processing

One step of the production line is to process the raw stone. This includes the collection, transportation, preliminary screening and dust removal of raw stones. Reasonable raw stone processing can ensure the smooth progress of subsequent processes.

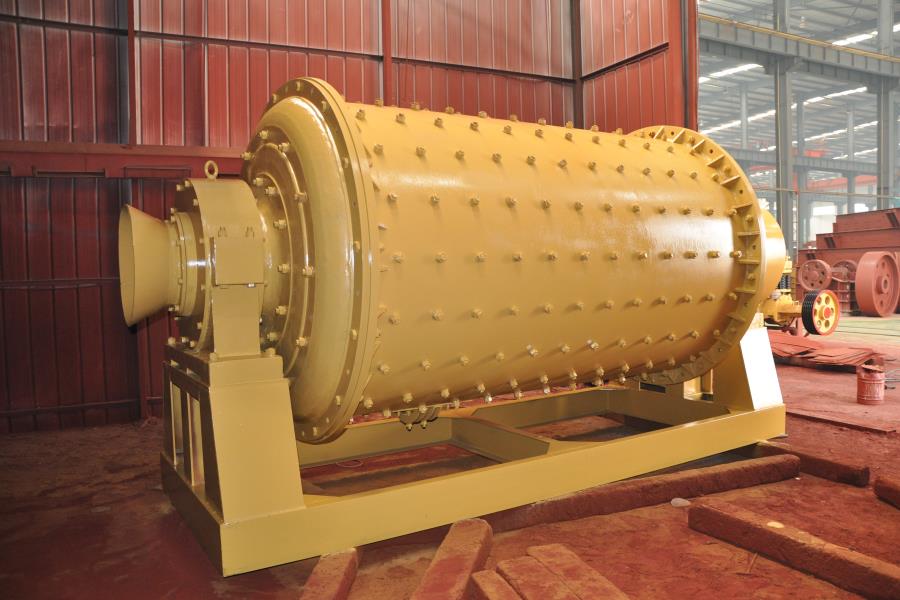

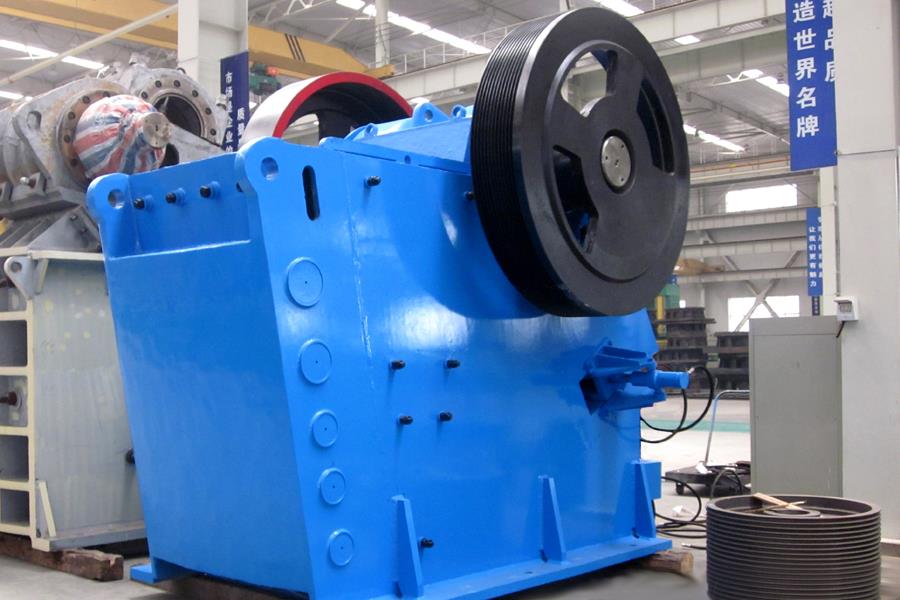

3. Stone crushing equipment configuration

After the raw stone is processed, stone crushing equipment needs to be configured, including jaw crushers, impact crushers, etc. The selection of these equipment should be reasonably matched according to factors such as the hardness and water content of the raw stone to improve the efficiency of stone crushing.

4. Sand making equipment configuration

Sand making is one of the key links of the production line. Common sand making equipment includes sand making machine, impact crusher, etc. By reasonably configuring these equipment, sand materials that meet the standards can be produced for use in construction, roads and other fields.

5. Screening equipment configuration

Screening the products after sand making is to meet the construction needs of different specifications. Reasonable configuration of screening equipment can produce sand and gravel products of various specifications that meet the requirements.

6. Finished product transportation and storage

Finally, the conveying equipment is configured to transport the finished products to the designated location, and storage equipment is set up to ensure the quality and safe storage of the products.

OCP Machinery Company has been focusing on the production and manufacturing of mining machinery and equipment for nearly 40 years. It has rich experience and mature technology. It can tailor exclusive production line equipment for you according to your actual production needs. In addition, it is a direct sales manufacturer with no intermediate links and more economical prices. Friends with needs can click to consult preferential quotations at any time. Customer service is online 24 hours a day.

-

Causes and solutions for abnormal vibration of vertical shaft impact sand making machine

-

How to configure a granite sand production line with an output of 1000 tons per hour

-

What is the commissioning price of a mobile crushing station