Introduction to the process flow of gangue brick making

Gangue brick making is a process of producing bricks using waste materials such as gangue, which has the characteristics of comprehensive resource utilization and environmental protection. The general process flow of gangue brick making is introduced below.

1. Gangue collection and preparation

Gangue is a waste generated in the production process of coal mines, containing a certain proportion of coal and rock. First, it is necessary to collect gangue, and after preliminary cleaning and screening, remove impurities in it to improve the effect of subsequent brick making process.

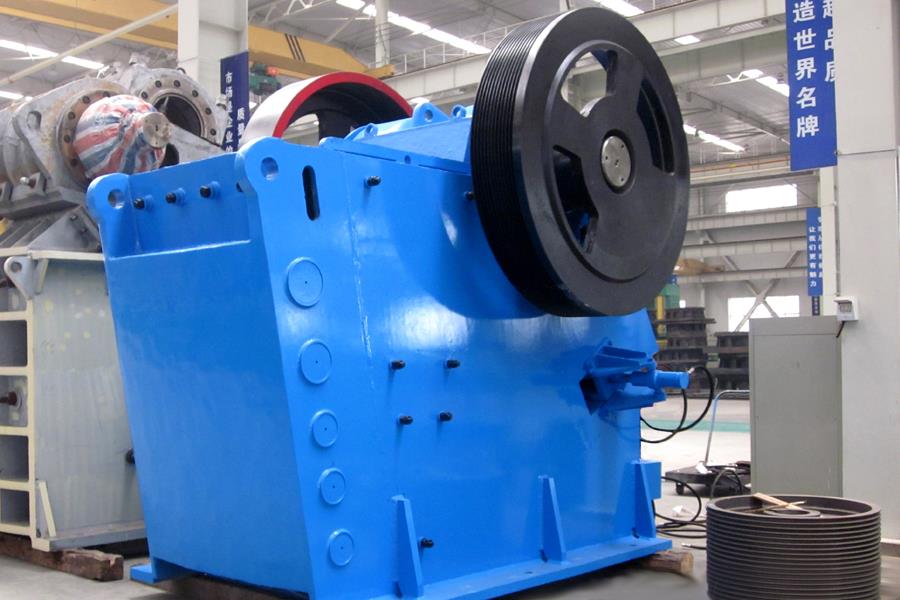

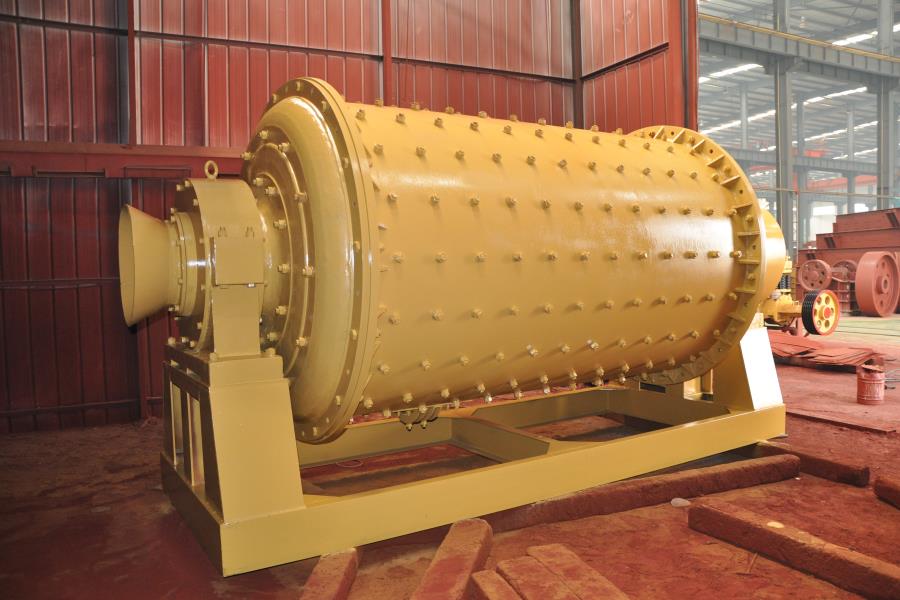

2. Gangue crushing and mixing

The collected gangue is coarsely crushed by crushing equipment to break it into appropriate particle sizes. Then, the crushed gangue is mixed with an appropriate amount of cement, lime and other admixtures. A certain ratio needs to be maintained during the mixing process to ensure the strength and stability of the bricks.

3. Brick blank molding

The mixed gangue material is fed into a brick machine or press and formed into a brick blank through a mold. The design of the mold usually determines the specifications and sizes of the bricks according to the needs. The bricks after molding have a certain shape and density.

4. Brick curing

The bricks after molding need to be cured so that they can gradually harden and form under certain humidity and temperature conditions. The curing time and environment vary depending on the material ratio, and generally take several days to several weeks.

5. Brick firing

The cured bricks enter the kiln for firing. During the firing process, the bricks experience high temperatures, and cement and lime react to form a solid brick body. The firing temperature and time are also important factors affecting the quality of bricks.

6. Brick packaging and sales

After firing, the gangue bricks formed have certain strength and durability. Finally, the bricks are packaged and can be put on the market for sale after meeting relevant standards for use in construction and other fields.

The process of making bricks from gangue realizes the reuse of resources through the comprehensive utilization of abandoned gangue, while also reducing the demand for traditional building materials, with dual benefits of environmental protection and economy.

OCP Machinery Company has been focusing on the production and manufacturing of mining machinery and equipment for nearly 40 years. It has rich experience and mature technology. It can tailor-make exclusive production line equipment for you according to your actual production needs. In addition, it is a direct sales manufacturer with no middle links and more economical prices. Friends in need can click to consult for preferential quotes at any time. Customer service is online 24 hours a day.

-

Causes and solutions for abnormal vibration of vertical shaft impact sand making machine

-

How to configure a granite sand production line with an output of 1000 tons per hour

-

What is the commissioning price of a mobile crushing station