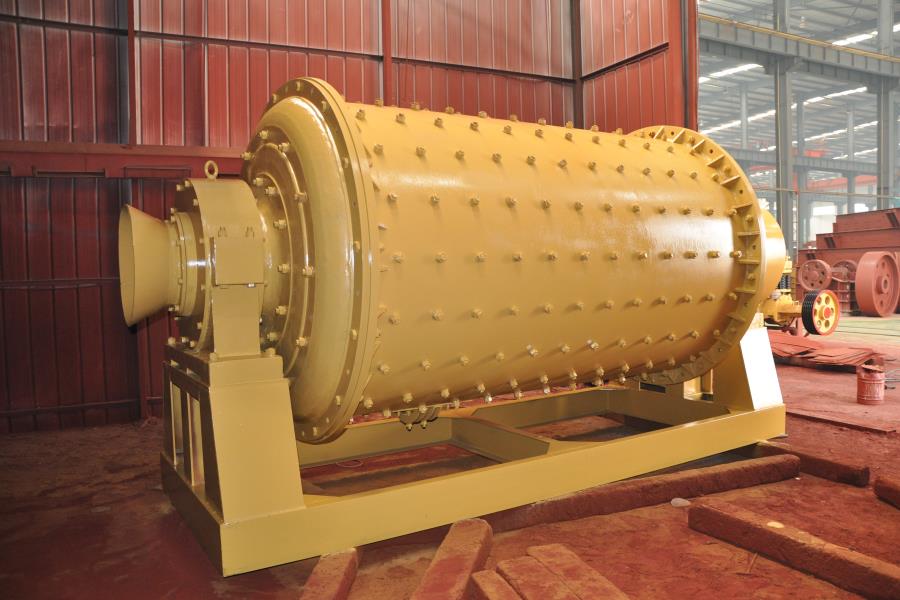

How to reduce the waste caused by the ball mill in operation

The ball mill is mainly to grind the material until it reaches the qualified particle size. However, during the operation of the ball mill, due to various reasons, excessive crushing will cause the particle size to be unqualified. In order to prevent this phenomenon, the ball mill should be in operation. Pay attention to these details:

1. Before installing steel balls, determine the appropriate diameter steel balls and make a good ratio of steel balls.

2. The feed particle size should be controlled within the allowable range of the ball mill equipment.

3. To control the movement state of the grinding medium, the throwing state should be the main one.

4. Check regularly, and determine whether to increase the number of balls according to the condition of the material after grinding.

5. While removing the ground materials in time, add new coarse materials in time to keep the accumulation of coarse materials at a high level.

Excessive crushing will not only waste a lot of raw materials, but also a great waste of manpower and production time. Users are reminded to grasp every detail when running the ball mill equipment to prevent excessive crushing.

If you need to purchase ore crushers, sand making machines, pulverizers, mobile crushing production lines and other related equipment, please consult the website customer service, 24 hours online.

-

What should be paid attention to in the routine inspection of the ball mill

-

All machinery must be shut down when repairing sand making equipment