What are the small machines for hitting stones

What is the name of small stone hitting machine? Also known as small stone beater, small stone crusher, mainly a variety of large ores processed into different specifications of stone (05, 12, 13, 24, etc.), the equipment is small in size, the operation is more convenient, and the efficiency is not low, there are more types of machines on the market, what are the specific small stone beater machines?

Small stone hitting machine more types, about a dozen models, of which the more commonly used four kinds, respectively, jaw stone hitting machine, hammer stone hitting machine, composite stone hitting machine and roller stone hitting machine, to meet the different production needs of small and medium-sized enterprises, the specific choice of which, combined with the actual needs to choose.

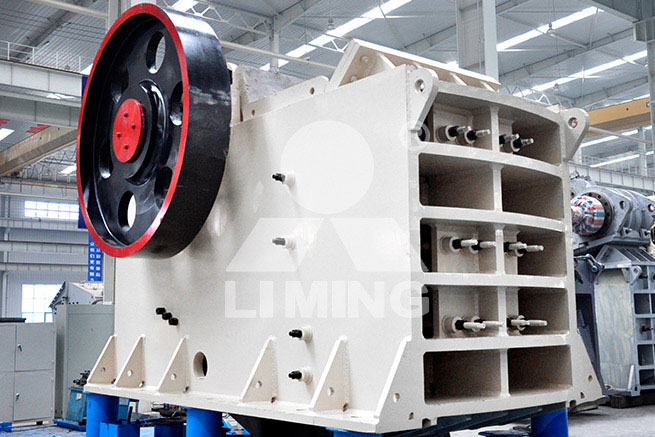

1.Jaw stone beater. Various hardness of ores and large materials can be processed, with coarse and fine crushing, using extrusion crushing principle, deep V-shaped crushing chamber, can make the material enter the crushing chamber without any obstacles, so as to ensure that the feeding capacity, coupled with the use of wedges to adjust the discharge port, the finished product size can be adjusted, uniform size, in addition, optimize the movement parameters, so that the material in the upper part of the crushing chamber can begin to work, the lower part of the stroke, the crushing ratio of The integrated structure of motor and host makes the installation easy and saves space.

2.Hammer type stone breaker. Apply to medium hardness and brittle materials, mainly rely on the impact of the hammer to crush the material, can be a finished product, join the modular design, through the replacement of the cavity type, adjust the coarse, medium and fine crushing, reduce the cost of 40% or so, the equipment has a compact structural design, occupies an area of less, in line with the small output, small batch operation requirements.

3.Compound stone beater. Applicable to a variety of hard and abrasive materials, the main technical parameters of the optimization of the design developed into a new type of fine crushing/coarse grinding products, to achieve a single operation, the use of stone working principle, the crushing ratio is large, coupled with the setting of no sieve bars, mud-containing materials is not easy to block, the moisture content of up to 8% or so, the overall efficiency of the enhancement of the three-dimensional design, so the footprint is small.

4. Roller type stone beater. Applicable to all kinds of medium and high hardness materials, the roller design, through the two rollers between the extrusion crushing, driving device are by two electric motors, kinetic energy is more powerful, the same capacity to save energy consumption of 45%, and higher production efficiency, the grinding rollers have uneven teeth on the surface, but also sand processing, high yield, good particle size, low content of needles and flakes.

Our company adopts direct sales mode, direct delivery of products to customers, the price of full transparency, to ensure quality at the same time can reduce the cost of fees for customers, really provide customers with good value for money mining equipment. Click on the customer service free consultation, to provide you with more professional investment reference.