What are the crusher with 300 tons per hour capacity for limestone

Limestone generally refers to limestone, calcite as the main component of carbonate rock, with thermal conductivity, solidity, water absorption, impermeability, acoustic insulation, abrasive, very good cementing properties, can be directly utilized in the original ore, but also can be deeply processed and applied, of which what are the crusher with a capacity of 300 tons per hour of limestone?

Limestone is mainly formed in the shallow sea environment, the hardness is generally not large, usually about 3 levels, easy to mine and process, the structure is more complex, there are two kinds of crumb structure and grain structure, according to the relevant qualities, the use of jaw crusher, impact crusher and hammer crusher is more suitable for the specific choice of which limestone crusher, combined with the actual production needs to choose.

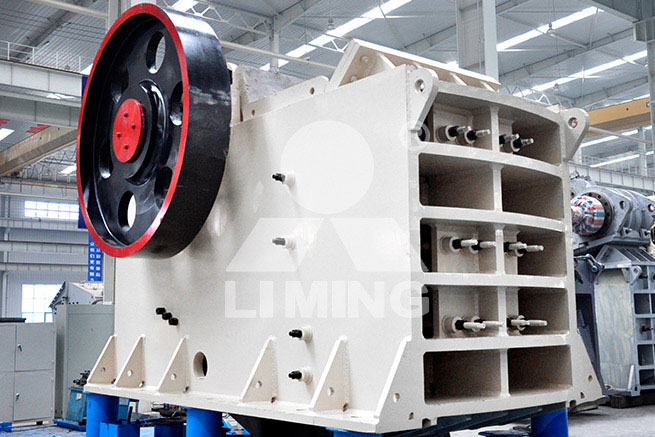

1. Jaw crusher is suitable for limestone production line, a section of coarse crushing, because of its optimized movement parameters, deep V-shaped crushing chamber depth, no dead zone, using the crushing principle of extrusion, through the movable jaw and static jaw two jaw plates form a crushing chamber, simulating the movement of the two jaws of the animal to complete the operation, and the crushing ratio is bigger, with wedge to adjust the discharge opening, the finished product size can be adjusted, uniform size, while the motor seat and host integrated structure, making the At the same time, the integrated structure of motor base and main machine makes it easy to install and saves space.

2. Impact crusher is suitable for two-stage medium and fine crushing, adopting new concept of crushing technology, the material is crushed by repeated impacts between the plate hammer and the impact plate to meet the requirements of the new technology of more crushing and less grinding, with high rate of finished products, cubic, good grain shape and less powder, strong rigidity, large rotor inertia, and convenient adjustment of the gap between the impact plate and the plate hammer to control the particle size of the material, and it is more in line with the standard of the initial cost investment. Low cost in the early stage and high cost of maintenance and replacement in the later stage.

3. Hammer crusher rely on the impact of the hammer to crush the material, a molding, reducing the process, can directly crushing size 1000 mm limestone to 05, 12, 13 and other stones, by replacing the cavity type, you can realize the conversion of coarse, medium and fine crushing, eliminating the process of primary crushing, and no longer need the second stage of the crushing process, no flake, no smooth body, polygonal prisms to ensure the compressive strength, and at the same time to improve the production It also improves the production efficiency and reduces the operation cost.

OCP Machinery Company focuses on the field of large-scale industrial grinding, ore crushing and sand making, and is specialized in the research, development, production and manufacture of Raymond mill, ultra-fine mill, European mill, high-pressure mill, impact crusher and jaw crusher. We insist on pre-sale technicians to visit the site, free guidance and planning, and provide detailed production programs. After-sales equipment installation quickly in place, the first time for customers to solve practical problems. We have won the praise of customers at home and abroad. Consult the website customer service, 24 hours free consultation.