What are the application areas of silicon carbide grinding machine

Silicon carbide is rare in nature, mostly synthetic, made from quartz sand, petroleum coke, wood chips and other raw materials by high temperature smelting in resistance furnace. Silicon carbide is one of the most widely used and economical minerals, so it is valued by many investors, however, the market demand for silicon carbide continues to increase, the requirements of silicon carbide powder continue to improve, which requires special grinding equipment for its production.

To say that the development of the application of silicon carbide grinding machine that have to mention the application areas of silicon carbide. It can be said that silicon carbide grinding equipment can have a good development, can not be separated from the wide application of silicon carbide in all major fields:

1. Corrosion resistance, high temperature resistance, high strength, good thermal conductivity, impact resistance of the three resistant materials for a variety of smelting furnace lining, high temperature furnace and kiln components, silicon carbide plate, lining, support, sagger, silicon carbide crucible, etc., in addition to non-ferrous metal smelting industry can be done for high-temperature indirect heating materials, such as vertical distillation furnace, distillation furnace tower plate, aluminum electrolytic baths, copper melting furnace lining, zinc powder furnace arc type plate, thermocouple protection Tube, etc.; for the production of wear-resistant, corrosion-resistant, high-temperature-resistant high-level silicon carbide ceramic materials; can also be made of rocket nozzle, gas turbine blades, etc.. In addition, silicon carbide is also one of the ideal materials for highways, airplanes, runways, solar water heaters and so on.

2. It can be used as the deoxidizer of steelmaking and the improver of cast iron organization, and can be used as the raw material for manufacturing silicon tetrachloride, which is the main raw material of silicone resin industry. Silicon carbide deoxidizer is a new type of strong composite deoxidizer, replacing the traditional silicon powder carbon powder for deoxidation, and the original process compared to the physical and chemical properties are more stable, deoxidizing effect is good, so that deoxidizing time is shortened to save energy, improve the efficiency of steelmaking, improve the quality of steel, reduce the consumption of raw and auxiliary materials, reduce environmental pollution, improve the labor conditions, and improve the comprehensive economic efficiency of the furnace are of great value.

3. It is used to make grinding wheels, sandpaper, abrasive belts, oil stones, grinding blocks, grinding bits, grinding paste and photovoltaic products in monocrystalline silicon, polycrystalline silicon and piezoelectric crystals in the electronics industry, such as grinding, polishing, and so on.

4. Using its thermal conductivity, heat radiation, high heat intensity characteristics, the manufacture of thin plate kiln furniture, not only to reduce the capacity of the kiln, but also improve the kiln's loading capacity and product quality, shorten the production cycle, is the ceramic glaze baking and sintering of the ideal indirect materials.

5. The use of good thermal conductivity and thermal stability, as a heat exchanger, combustion consumption by 20%, saving 35% of fuel, so that productivity increased by 20-30%, especially the discharge of the mining plant with the discharge of the pipeline within the release, the degree of wear-resistant is ordinary wear-resistant materials 6 - 7 times.

6. Synthetic Silicon Carbide (Synthetic Moissanite), also known as synthetic moissanite, synthetic carbon silica (chemical composition SiC), dispersion 0.104 than the diamond (0.044) is larger than the refractive index of 2.65-2.69 (diamonds 2.42), has the same diamond luster with diamonds, "Fire Color "Stronger, closer to diamond than any previous imitations.

7. Sandblasting rust removal, using brown corundum micro-powder by high pressure extrusion, high temperature sintering molding, moderate hardness, clean and clean, not easy to break. It can be used repeatedly for many times with good sandblasting effect.

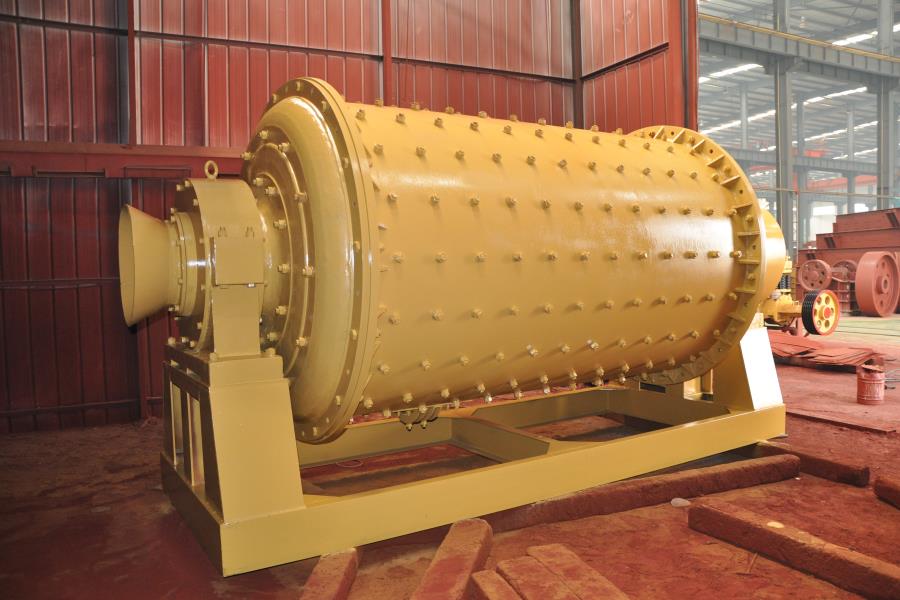

Because of such a wide range of applications of silicon carbide, creating an advanced development status of silicon carbide mill, but at present the country can produce a limited number of manufacturers of silicon carbide mill, users need to be careful when buying, different grinding equipment if used for the grinding of silicon carbide powder, there will be a low yield, the finished product fineness is not up to the standard, the mill wearing parts are subject to a short life cycle and other phenomena, and the special grinding mill can be very good to avoid these problems.

We are a professional manufacturer of crushing and grinding equipment, we will provide you with advanced equipment and perfect service! Welcome customers to visit us, negotiate business, sincere cooperation and create brilliant. Click customer service free consultation, 24 hours online, looking forward to your message.