How to improve the service life of grinding machine bearings

1. In accordance with the milling equipment, each component should use the specified installation tools, especially the grinding rollers, grinding rings, bearings and other precision parts, in addition to the installation is also required to check carefully after the completion of measurement with a professional instrument to check that there is no error before production work.

2. Each type of mill is equipped with a detailed instruction manual, each component to add lubricant type, cycle, cleaning time schedule, etc., of course, special circumstances require special treatment, for some production intensity of the production line frequency should be more frequent, pay more attention to the inspection and maintenance, add the amount of lubricant, add the way should be accurate, on the lubricant has been contaminated must be thoroughly cleaned up after the replacement of a new lubricant can not be, don't lose a great deal of money because of small losses. Do not make a big mistake.

3. bearing installation in other parts is different, there is a certain sequence and time limitations, according to the completion of the sealing must keep up, some manufacturers Raymond Mill only two sealing devices, the effect is poor, from time to time into the powder contamination of the bearings, and Zhengzhou OCP mill, the use of five sealing devices, sealing effect is good, you can strictly control the entry of the amount of dust to prolong the use of the period of time cycle.

4. Avoid high temperature, fatigue operations, when the temperature is found to exceed the safe use of the range, should be shut down to dissipate heat or use certain cooling measures, OCP also recommends that users of the production work and rest should be planned, try to avoid long-term continuous operation.

5. Select the manufacturer is also the key, recently came to our factory to visit Mr. Wang said that he bought the Raymond mill bearings are always damaged, almost two days to be replaced once, a very big headache, and before the manufacturer contacted people to overhaul is has not been repaired, which is ready to change the machine, the factory in line with the customer's point of view, to understand the cause of its failure in the grinding roller assembly, so we recommend that users only need to replace the assembly.

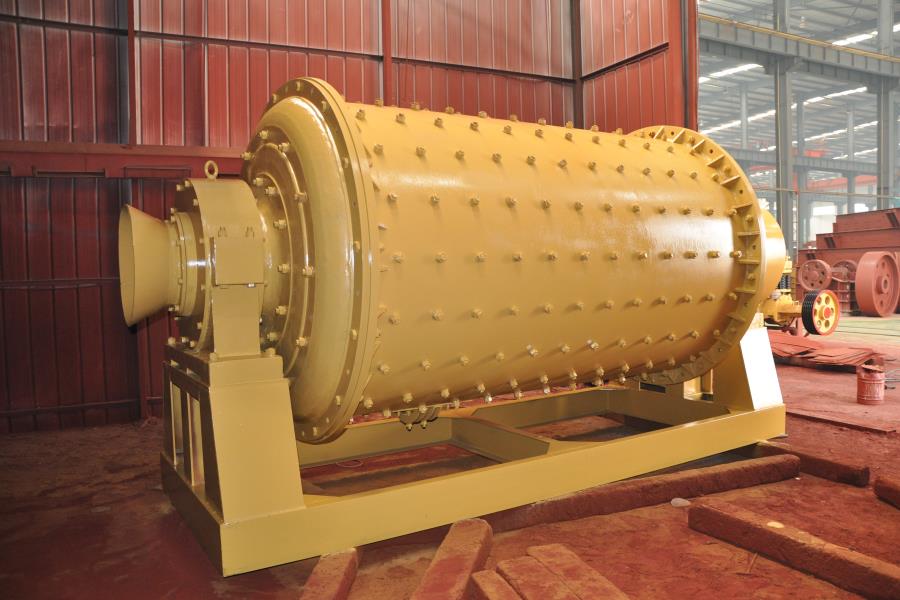

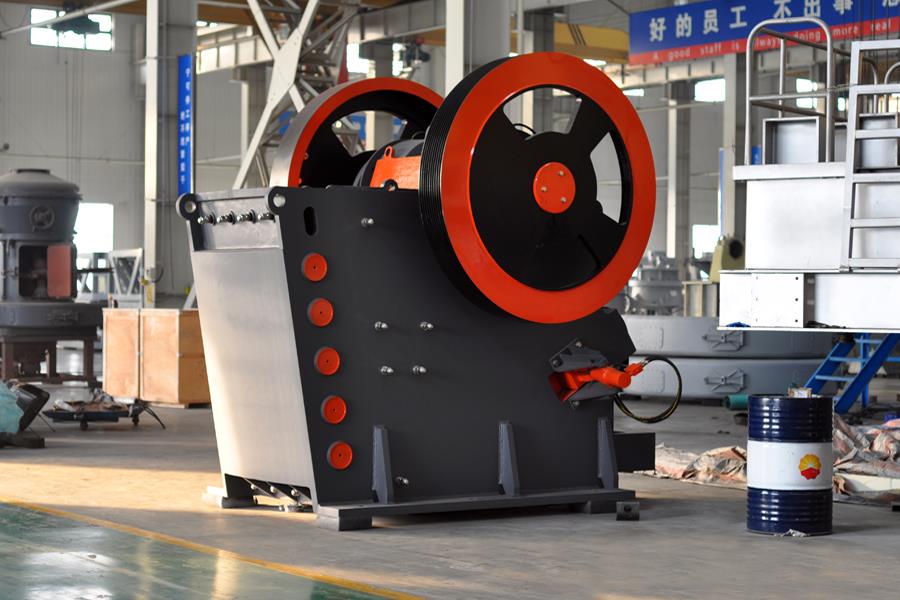

We are a professional production of crushing and grinding equipment source manufacturers, strict control of product quality, pre-sales, after-sales are responsible for professional staff, all the way to escort you. We not only provide you with advanced crusher and grinding equipment, but also perfect service! Click customer service free consultation, 24 hours online, looking forward to your message.