Mill feeding uniform method and the impact on the finished material

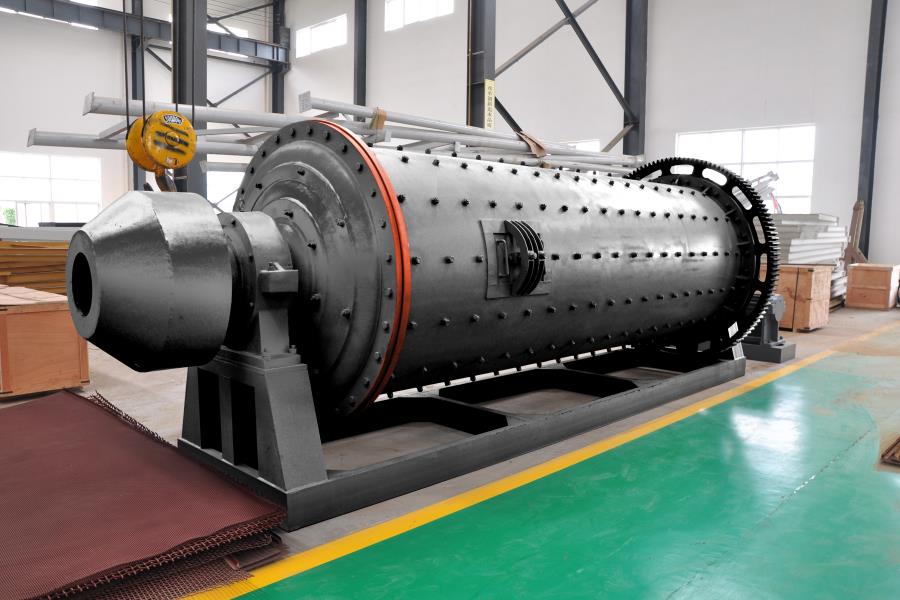

In the mill grinding process, perhaps many people only notice the importance of the mill, while ignoring the significance of other auxiliary equipment, such as electromagnetic vibrating feeder uniform and orderly feeding device is an indispensable part of the entire grinding production line, but also the relationship between the quality of the finished product and the key to yield.

Some companies in order to save equipment costs, that as long as the grinding host equipment is advanced, reliable quality, the quality of the finished product is not a problem, this idea is obviously not right, artificial feeding there are great disadvantages, due to the limitations of manpower strength, in the feeding process is difficult to protect the uniform feed rate, uneven feeding will lead to uneven fineness of the finished product, the finished product quality can not be guaranteed, etc. To solve the problem of Raymond mill feeding, many manufacturers choose to use automatic feeder. To solve the problem of Raymond mill feeding, many manufacturers choose to use automatic feeding devices to avoid uneven feeding, such as electromagnetic vibrating feeder, etc., machine equipment has a great advantage is how to control the programme, there is no doubt about the implementation of, and is the completion of the quality and quantity. So this kind of powder production process is recommended to choose the automatic control device, the cost of the equipment is a slight increase, can be compared with the cost of labour to see, which is the lesser of the two needless to say we all understand.

So what is the impact of uneven feeding mill? First of all, the quality of the finished product is certainly affected, followed by the output, and then on the service life of the grinding equipment also has an impact. Feeding too little, can not reach the grinding standard, the equipment is like running on empty, on the one hand, low productivity, high energy consumption, cost consumption is serious, on the other hand, running on empty grinding rollers, grinding ring interaction wear and tear accelerated; feeding too much, grinding equipment is prone to clogging, finished product size is not uniform, fineness is not up to standard, the equipment is in the load movement under the output will also be reduced; if more or less is more unfavourable, resulting in Raymond Mill Powder machine load fluctuations, the quality of the finished product naturally can not be guaranteed, and the equipment is in an unsafe operating state, prone to accidental failure; therefore, feeding uniformity has a significant impact on the powder processing, OCP reminds us not to ignore such details, Raymond mill stable and balanced working condition of the finished product of the material and its own service life have an important role.

Especially in the development of science and technology today, quality is always the direction of the pursuit of enterprise, the quality of the powder material requirements are also higher and higher, to set the threshold for milling manufacturers, but also to the mill manufacturers to exert pressure, grinding equipment technology to improve, perfect the process, the development and production of new mills is the most important concern at this time, and feeding uniformity is not a problem now, why not let it be appropriate to make full use of it.

We will be responsible for each machine sold, dedicated to provide first-class service for Chinese and foreign businessmen, our mine crusher price is fair and reasonable, welcome new and old customers at home and abroad to visit and guide the work! Click customer service free consultation, 24 hours online, looking forward to your news.

-

How to replace Raymond mill wearing parts serious wear and tear

-

Life everywhere stone powder should choose what kind of grinding equipment processing

-

The correct sand washing process will bring considerable benefits

-

Finished material particle size and Raymond mill which factors related to and how to control the

-

Green silicon carbide micropowder leads the mill on the new energy road