Green silicon carbide micropowder leads the mill on the new energy road

Green silicon carbide powder is now a new energy photovoltaic industry, a cutting auxiliary materials, processing and black silicon carbide similar, but the requirements of the raw material is different, green silicon carbide mill grinding, powder in the green energy science and technology is widely used, but also a new type of green materials.

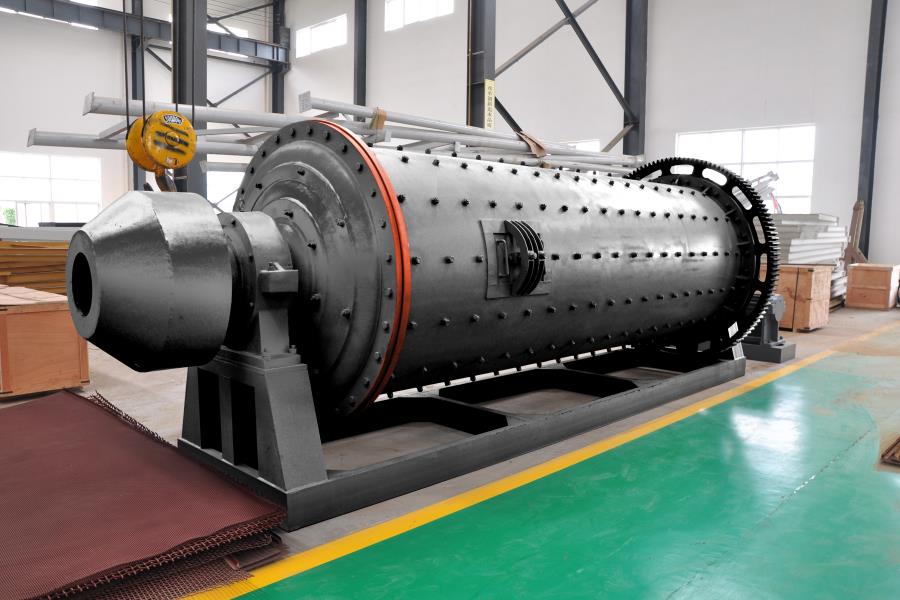

Due to the intensification of the global greenhouse effect, Antarctic glaciers began to slowly melt, about 300 billion tonnes per year will disappear, the control of carbon dioxide content in the air should be paid attention to, coupled with the growing consumption of non-renewable energy sources, the energy crisis has also become part of the problem that countries must face, looking for renewable resources has become the focus of world attention, low-carbon environmental protection, green energy has become the direction of the future economic development. With the development of science and technology, solar energy technology has become one of the 21st century renewable and high value of green energy, environmental protection, high efficiency and renewable resources, the development of photovoltaic industry not only can effectively solve the problem of resource shortages, to improve the economic status quo, but also as a renewable resource in the development of the new century has become the mainstream industry. The photovoltaic industry in the crystalline silicon cell cutting technology is inseparable from the green silicon carbide powder and other auxiliary materials, green silicon carbide is mainly petroleum coke, high-quality silica and other materials in the resistance furnace high-temperature smelting, and then by the ultra-fine Raymond mill and other milling equipment and grinding from the development of photovoltaic industry has also led to the development of the powder industry, the development of the mining industry, regardless of the high-quality silicon, or smelting of the green silicon carbide can not be separated from the crusher, grinder and other processing equipment! The production of green silicon carbide powder has also become an indispensable part of the photovoltaic industry.

Green silicon carbide micropowder in the photovoltaic industry, but also industrial mill on the road to a new type of green energy, Raymond mill, crusher and other mining machines have long been not only limited to the development and utilisation of mineral resources, in the development of green materials, industrial slag, solid waste recycling and so on have an important role. Powder particles use value is constantly being tapped, grinding equipment technology in all aspects of technical performance also need to be constantly improved to meet market demand, green equipment is the world's common development goals and direction.

If you plan to configure a crushing and grinding production line, you can leave a message to tell us what equipment you are interested in, what materials you need to crush, as well as your output and other requirements, etc., we will arrange for professionals to dock with you. You can also directly click on the website customer service, 24 hours online, to provide free consulting services!

-

The application of the mixing plant grinding machine is different by the geographical restriction

-

Raw fluorspar many uses need to rely on the ore mill grinding to achieve the

-

Analysing the crushing and grinding process of limestone by its different uses