Measures to improve the life cycle of the hammer crusher

Limestone, coal, gypsum and other soft materials crushing selection of hammer crusher more, one because the hammer crusher is simple to operate, easy to transport, the second is inexpensive, low investment costs, but the hammer structure of the crushing has a more obvious disadvantage of the use of the cycle is short, such as impact crusher, heavy hammer crusher, fine crusher and also how to improve its service life, to extend the role of time, today, I made a summary of this issue to you.

Hammer crusher short life cycle refers to the life of the hammer head, hammer head, rotor, castor crusher three major wearing parts, hammer crushing principle of impact, shear, tearing and other ways to complete the crushing process of large objects to small objects, iron to stone, stone to stone crushing of the crushing parts of the wear and tear of serious, if the hammer head material shoddy, the life of the shorter, the normal use of the hammer cycle of 4-6 months or so, if the material is too hard or shall not be used for two weeks Will be scrapped, or even shorter cycle, castor, rotor life to be slightly longer than the hammer, thus analyzing the wear and tear of the hammer head is mainly in the material crushing stage of impact friction and wear, know the specific reasons can be taken to prevent the method of measures to protect measures are mainly from the start-up preparations, operation, shutdown maintenance of the three aspects of the starting point.

Preparation before starting:

1. Ensure the integrity of the machine, such as the hammer head liner with or without damage, whether the bolt parts are loose, whether the connection between the constituent parts is good, etc., and found that the accessories are loose in time to tighten the problem.

2. Whether there is a lack of lubricant in the running parts of the machine, find oil leakage, less oil to add timely repair.

3. Before running the crushing equipment, we should make sure that there is no iron and other non-crushable materials in the crushing chamber, and keep the crushing chamber clean.

Operation precautions during operation:

1. The selection of materials should be within the scope of application of the hammer crusher, the hardness of too large to accelerate the wear of the hammer head.

2. Small machines can be manually fed, large hammer breakers need to feed the feeder to feed evenly.

3. Before the equipment is put into production, it is better to test run the machine to make sure whether each component structure can operate normally.

4. If you hear strange noise in the crushing, such as knocking sound, metal impact sound, etc., you need to stop the machine to check the situation in the cavity, troubleshooting after Zai resume production.

5. The size of the raw material is controlled within the requirement of the feeding port of the hammer crusher.

6. The feeding volume should not exceed the maximum capacity of the crushing equipment, otherwise it will cause overloading and damage the machine parts.

7. Reasonable arrangement of machine operation time to avoid long-term overwork operation.

8. The crushing machine should be shut down to check the cause of over-temperature, especially the maximum temperature of the bearing part should not exceed 70℃.

Overhaul and maintenance after stopping the machine:

1. Check the crusher after stopping the machine, and check the integrity of the accessories, whether there is any missing or damage.

2. Pay attention to clean the work site, especially the bearings and other precision parts, clean up the internal dirt, need to lubricate the parts to add lubricant.

3. If you need to replace the hammer head and other wearing parts, do not use the hammer tool to directly hit, to prevent damage caused by the loading and unloading process, in addition to a section of the bearing at both ends of the rotor want to damage, you need to replace the two ends or thoroughly cleaned after the replacement of the damaged end, do not save a moment of trouble and carelessness.

4. Spare wearing parts and other accessories should be prevented from being stored in a dry and clean location, and pay attention to the surface of the oil and rust inhibitor to prevent rust.

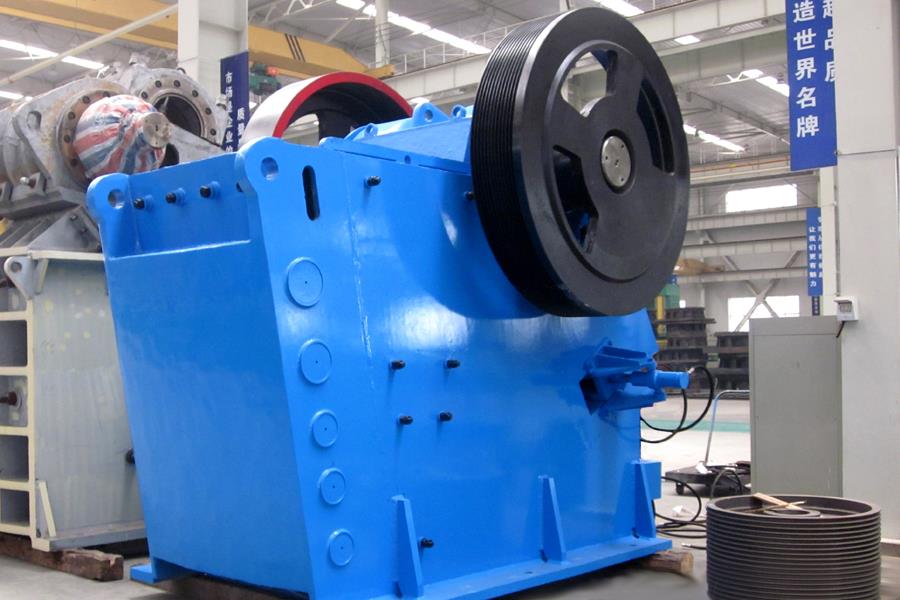

Special reminder: hammer crusher should be powered on first after feeding, shutdown should first stop feeding in the shutdown, which is detailed in the instructions for use of the equipment, you can also refer to OCP's product center hammer crusher equipment details, hammer crusher in the soft materials are more commonly used, if the hardness of the recommendation to choose the jaw crusher, cone crusher and other extruder crusher for better results. Welcome to visit our factory at any time, welcome to click on the website customer service consulting, 24 hours online.

-

Hydraulic cone crusher crusher is a new type of high-efficiency stone crusher

-

Cone crusher accessories hydraulic cylinder installation instructions