Feasibility analysis of single-section heavy hammer crusher

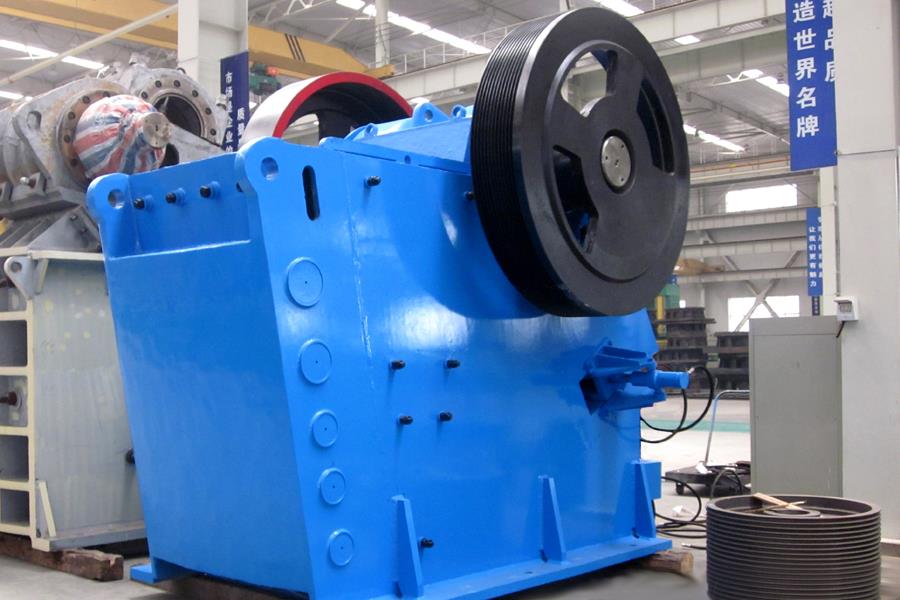

Mention of single-section heavy hammer crusher, perhaps not as familiar as the jaw crusher, heavy hammer broken belongs to a new type of crushing equipment machine, suitable for hardness of soft ores, stone, sand and gravel production, general to make a detailed feasibility study on this analysis report can be used as a reference, today, I would like to take you to a comprehensive understanding of what is a heavy hammer stone crusher, its principle, application, characteristics and feasibility analysis.

Principle of operation:

The material enters into the crushing chamber, stacked on the ad hoc intermediate bracket in the machine, the hammer head runs in the gap of the intermediate bracket, crushing the material continuously and falling, the falling small pieces are further struck by the high-speed hammer head and finely crushed, and finally discharged after the curved plate is integrated into the compartment.

Main use:

Used for crushing coal, salt, chalk, gypsum, masonry, limestone and other materials with little hardness, in addition to the fiber structure, elasticity and toughness of broken wood, paper or crushing asbestos cement waste to recover asbestos fibers, etc., Heavy Hammer Crusher is not only used in crushing production line, sand production line, but also in the beneficiation production line to replace the cone crusher.

Performance Characteristics:

1. A single-section heavy hammer crusher can replace two jaw crushers of coarse crusher and fine crusher, change tertiary crushing into primary crushing, reduce equipment investment by 50%, and the efficiency is not reduced.

2. Large feed size, small discharge size, large crushing ratio, large weight of a single hammerhead, high rotor speed, durable hammerhead, such as a large weight of a single hammerhead (about 80 kilograms), the life of the hammerhead to improve the 4-6 times, each hammerhead can be crushed stone 30,000-40,000 tons, crushing 0-70 mm building stone.

3. Single-section heavy hammer stone crusher wins in details, wins in quality, make full use of the principle of impact crushing, and improve the speed of the material running, so that the material produced between the self-collision, improve the crushing effect, the crushed finished product grain shape is good, more cubic, less needle flake content, so the material grains of high mechanical strength, suitable for high level highway, high-rise buildings and other industries, such as the crushing of stone materials.

4. Reasonable and compact institutional design, high and deep crushing chamber, increase the material crushing rate, the rotor consists of spindle, hammer disk, pin shaft, hammer head, etc., the disk is evenly distributed on the distribution of pin holes, with the pin suspension hammer head, in order to prevent axial fluctuation of the disk and the hammer head, with the locking nut at the two ends of the pin fixed.

OCP with its high yield and high efficiency, small system supporting power, low production costs and many other advantages recognized by the crushing customers, in the crushing and sand making process have been achieved multiple test results, the effect is remarkable, the single production line structure is simple, easy to move, can also be made into a mobile crushing plant better, welcome to click on customer service consulting, 24 hours online.

-

Hydraulic cone crusher crusher is a new type of high-efficiency stone crusher

-

Cone crusher accessories hydraulic cylinder installation instructions

-

Cone Crusher Thrust Bearing and Eccentric Sleeve Parts Explained

-

Raymond mill to help new building materials calcium silicate board production and processing