Large-scale fully enclosed environmentally friendly sand production line equipment configuration

With the increase in the number of social infrastructure projects, the demand for sand used for infrastructure has soared, stone processing sand industry prospects, in addition to the state of the gravel plant environmental control is strict, to build a large-scale closed environmental sand production line will be a wise choice to ensure that the gravel plant long-term stable operation, this article introduces you to the closed environmental sand production line needs to be configured with the equipment.

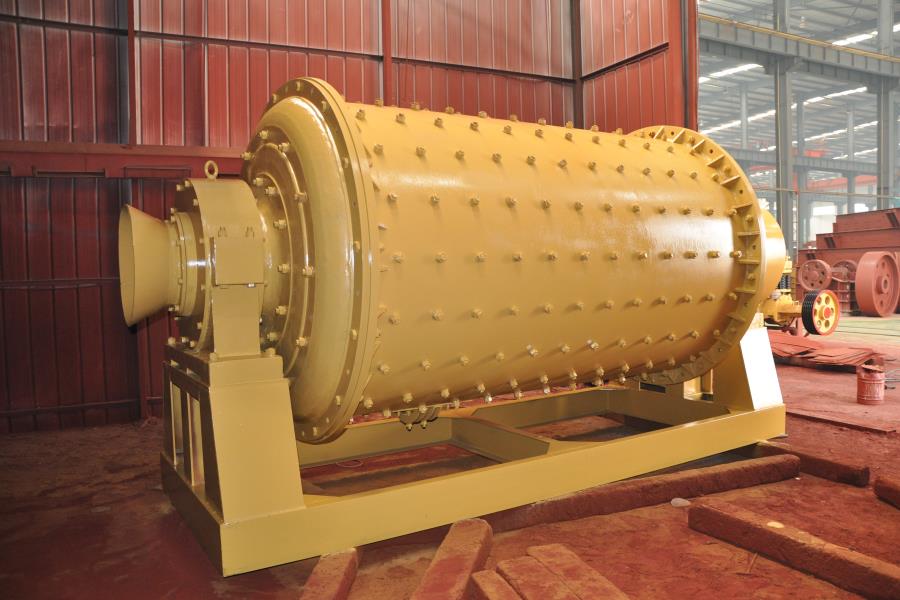

Scale construction of large-scale sand plant, it is recommended to use a three-stage crushing process, so that the processing of the mechanism of sand quality is better, three-stage crushing process, namely, coarse crushing, medium and fine crushing and sand shaping, the equipment used were jaw crusher, cone crusher/impact crusher and sand shaping machine. The sand making and shaping machine has both sand making and shaping functions, with better particle shape of the finished product, and new environmental protection design, automatic circulation in the vortex chamber, so that the dust does not overflow. In addition, it needs to be equipped with sand washing machine to clean the sand, which makes the finished product more pure.

Note: Cone crusher is suitable for processing granite, basalt and other high hard materials, impact crusher is suitable for processing lapis lazuli, coal gangue, dolomite and other medium hard materials.

In order to ensure environmental protection, alone to build a fully enclosed plant is not enough to meet the environmental requirements, indoor pollution sources are mainly dust, sewage and noise, a series of environmental protection measures should be taken to prevent pollution, to ensure that the production of environmental protection standards. Therefore, it is necessary to install dust collector to collect dust from the discharge port of the production line, assemble sealing cover for the conveyor belt to prevent the dust from overflowing during the conveying process, install acoustic enclosure for the crushing equipment to reduce the working noise, and build a sewage settling tank to filter the waste water from the sand washing, and the filtered clean water can be used for the sand washing again to realize the zero-discharge of waste water.

OCP is a professional manufacturer of crushing and sand making equipment, and customized production line design, from site selection, layout, installation to test run to the formal production is responsible for the whole process, the service is more intimate, factory direct sales, equipment to enjoy the factory price concessions, if you are interested in investing in a large-scale fully enclosed environmentally friendly sand production line, you can consult with our customer service online website, will be docked to the professional and technical personnel for you to want to explain the introduction of equipment, model selection and quote information. 24 hours a day, we have a lot of information about the equipment. Selection and quotation information. 24 hours online.

-

What kind of crusher is used to process shanmao stone and its finished stone specification

-

Basalt crusher with 500 tons per hour high material stone capacity

-

What are the equipment for 200 tons per hour silica rough processing crushing production line