What kind of crusher is used to process shanmao stone and its finished stone specification

Hickory is the rock on the mountain after blasting or artificial excavation of the irregular shape of the stone, hardness, density and chemical properties of the stable, generally crushed into small stones used in construction projects, so what need to use what Hickory crusher processing it? What specification of stone can be produced?

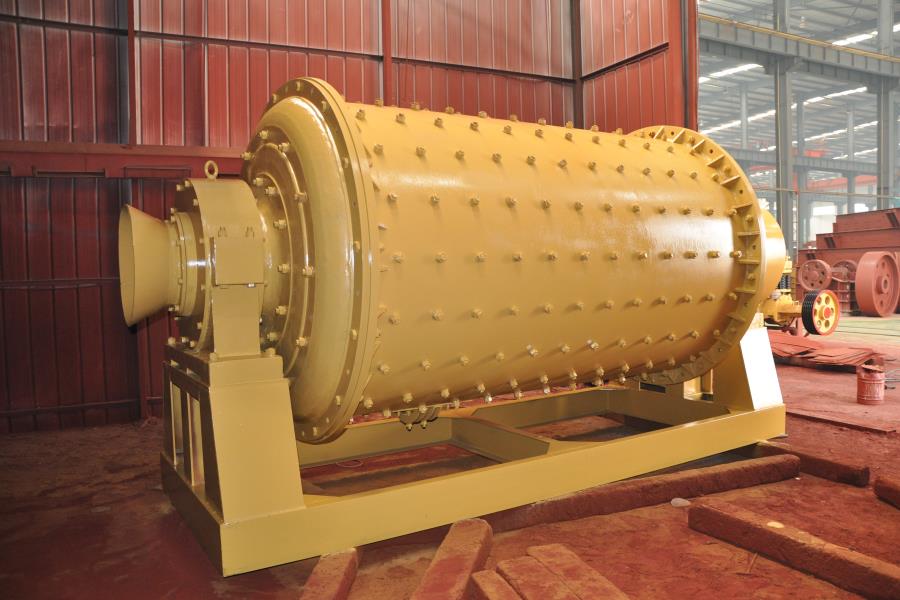

The processing of rocks into stones requires two crushing processes, the primary crusher are used jaw crusher, the second crusher selected cone crusher or impact crusher. Different specifications of finished stones can be processed, the following specifications and characteristics of the main parameters.

1.Jaw crusher

Parameters: capacity 1-2200t/h, feed size 120-1500mm, discharge size 10-350mm.

Features: strong crushing capacity, soft and hard materials, automatic control system, easy to operate, deep crushing chamber, increase throughput while strengthening the sealing, more environmentally friendly.

2.Cone Crusher

Parameters: capacity 12-2181t/h, feed size 35-560mm, discharge size 3-64mm

Characteristics: good crushing effect on granite, basalt, pyrophyllite, pebbles and other medium and high hardness materials, stone grain shape uniformity, low needle flake content, single-cylinder, multi-cylinder, fully hydraulic and other cavity types to choose from, to meet different production needs.

3.Impact Crusher

Parameters: capacity 30-2000t/h, feed size ≤ 1000mm, discharge size 5-60mm.

Characteristics: Impact crushing principle, the finished product has better particle shape, cubic, uniform particle size, suitable for crushing lime, dolomite, coal gangue, construction waste and other low-hardness materials, wear parts are made of high wear-resistant materials, long service life.

The second crushing equipment is responsible for processing large stones into small stones, the common stone specifications in the sand and gravel market are 51 stones (5-10mm), 12 stones (10-20mm), 13 stones (16-31.5mm), the cone crusher and impact crusher are able to process these specifications, and the discharge size of the equipment can be adjusted freely, and it is convenient for adjusting the discharge opening, which can be produced according to your demand.

OCP Machinery Company is a professional manufacturer of crushing and sand making equipment, with 40 years of development history, rich production experience and advanced technology, and the equipment have passed the quality system certification, so the quality is guaranteed. We can customize the production line design for you, welcome to click on the website customer service immediately free consultation, 24 hours online.

-

Basalt crusher with 500 tons per hour high material stone capacity

-

What are the equipment for 200 tons per hour silica rough processing crushing production line