What are the equipment for 200 tons per hour silica rough processing crushing production line

Silica is the general name of vein quartz, quartzite, quartz sandstone, which can be used to produce acidic refractory bricks for metallurgical industry, make quartz glass, ceramics, refine monocrystalline silicon, prepare silicate cement, and can also be used as filler for sulfuric acid tower. The utilization value of silica is high, crushing and processing is an important procedure to improve its economic value, next for you to introduce the specific 200 tons per hour silica rough crushing production line equipment and its price.

200 tons per hour belongs to medium-sized crushing production line, the daily output can be achieved about 1600 tons, in line with the demand of investors for large production and sales of goods. Silica whether it is rough processing crushing directly after use, or sent to the follow-up grinding deepening processing after use, crushing link is essential, the following for you to introduce the two types of production line specific configuration.

About 200 tons per hour silica crushing production line process flow

Program A: classic stationary silica crushing production line

1. Finished product specifications: 0-5mm, 5-10mm, 10-20mm, 20-30mm

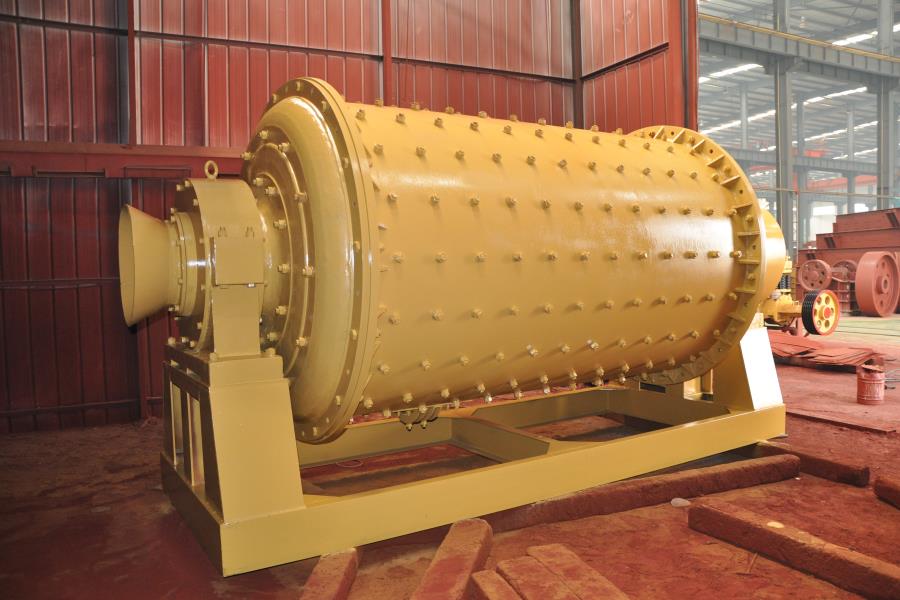

2. Equipment configuration: raw material bin, vibrating feeder, jaw crusher, conveyor, cone crusher, conveyor (can be more than one), vibrating screen, conveyor (can be more than one).

3. Production advantages: large crushing ratio, production ring, production can be controlled in stages; production of infrastructure required for perfect, one-time construction is completed, can be fixed to use, crushing operation is more stable and reliable; finished product storage space can be built freely, accumulation of goods storage is more convenient.

Scheme B II: Portable mobile silica crushing production line

1. Finished product specifications: 0-5mm, 5-10mm, 10-20mm

2. Equipment Configuration: Jaw Mobile Crushing Plant, Cone Mobile Crushing Plant

3.Advantages: mobile and flexible, can be easily transferred to the field of operation, can be called a mobile crushing production line, where there is a need to go where the operation; remote control operation, fully automated production, saving time and manpower; energy saving and environmental protection effect is outstanding, high production efficiency, can work continuously for 12-14 hours, the equipment is of high quality and durability.

200 tons per hour silica crushing production line process is: silica from the raw material warehouse through the vibrating feeder into the jaw crusher, coarse crushing process to 400mm or less, after the initial processing of silica through the conveyor conveyor to the cone crusher for the secondary crushing and processing process, and then will meet the standards of the stone conveyed to the vibrating screen for screening, can be screened out at the same time, 05, 12, 13, 24, which is the four different sizes of stone, and then conveyed to the vibration screen to screen, and then conveyed to the vibrating screen for the screening. size specifications of stones, and then conveyed to different finished products warehouse area for storage.

About the price of 200 tons per hour silica rough processing crushing line equipment

Although the quality of discharged finished products of fixed and mobile types are similar, there are some differences in equipment matching, plant construction cost, applicable sites, operation and maintenance. Hourly output of 200 tons of mobile silica crushing production line is a breakthrough of the traditional fixed type, more investment in research and development, technical difficulties, high production costs, comprehensive performance is more excellent, so but in terms of the purchase cost, mobile crushing equipment than fixed crushing equipment price is expensive, but a penny a penny, the price matches the value of the product.

In terms of the choice of production line equipment, equipment models, manufacturers, quality levels and other factors affecting the price is also more, which to a certain extent determines the diversity of the market offer, out of responsibility, it is difficult to accurately quote here, you can leave a message online or directly click on the customer service to inform you of your needs, etc., will be docking professionals to configure the production line and quote for you.

Click on the website customer service immediately free consultation, 24 hours online.

-

What kind of crushing equipment is used for processing waste refractory bricks

-

How to configure 100 tons per hour coal gangue mobile crushing plant

-

What are the environmental protection requirements for sand washing plant