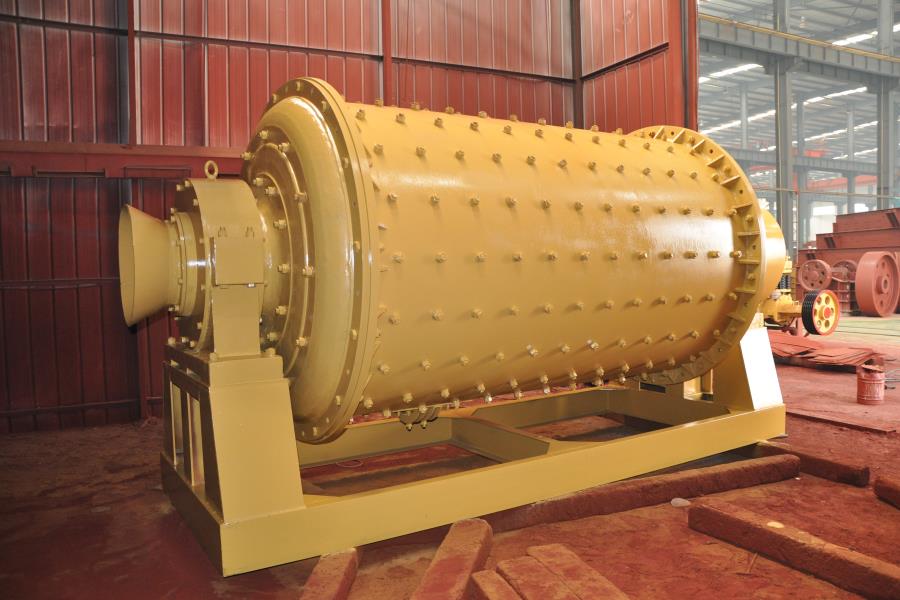

Ball mill start-stop problem in the milling production line

Ball mill is an ore milling production line will often be used in an ore milling processing equipment, we all know that for the ball mill this ore processing equipment, the correct operation of the machine has a great impact, here, we OCP machinery company and we say that the ball mill start and stop should follow what principle?

1. Before starting the ball mill equipment, we should carry out a comprehensive and detailed inspection of the mill and the affiliated equipment, and exclude all the faults that may affect the driving.

2. When driving, according to the direction of material flow from back to front one by one equipment to start, that is, the oil pump, a classifier, a ball mill, a belt machine, a feeder. It is strictly prohibited to start more than one piece of equipment at the same time; plan to stop from the front to the back (i.e., feeder, a belt conveyor, a ball mill, a classifier, an oil pump to stop.

3. Start each piece of equipment to have a certain interval, all the equipment started after the completion of normal and stable operation before feeding (such as the oil pump works normally and then start the ball mill, to be 2 ~ 3min after the ball mill operation and then start feeding).

4. Ball mill stopping in more than 4h, before driving the general need to carry out the disk car 2 to 3 turns, in order to loosen the bonded sludge and media.

5. Normal parking (planned parking) should be carried out under no load, as far as possible, the equipment within the material discharge (such as ball mills should be stopped after 15-20min after stopping the feed and then stop), for the next drive to create conditions.

6. Focus on reminding everyone, in the case of not feeding the mill running time should not be too long, usually less than 20min, so as not to consume steel balls and damage to the liner.

Welcome to click on customer service to understand the equipment mill price, production cases and other detailed information, 24 hours online free consultation.

-

Reasons for slowing down the crushing process of vertical composite crusher

-

Common problems and solutions in the use of marble sand making machine