What are the types of graphite crusher

Graphite is an allotropic isomer of carbon, chemically stable, corrosion-resistant, not easy to react with acids, alkalis and other agents, after a series of processes, can also be used for anti-wear agents, lubricants, electrodes, dry batteries, graphite fibers, heat exchangers, coolers, and arc furnaces, etc., but what are the types of graphite crusher?

Graphite crusher, also known as graphite crusher, more types, because of its soft, black gray, opaque solid, Mohs hardness of 1-2, specific gravity of 1.9-2.3, so the choice of jaw crusher, impact crusher is better, the specific choice of which, combined with the actual production requirements.

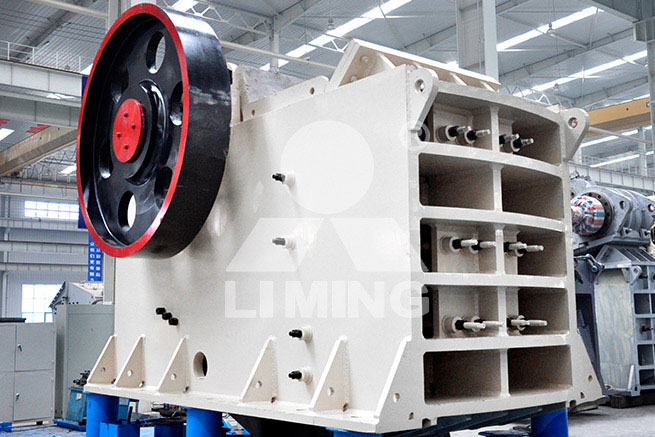

1.Jaw crusher

Jaw crusher has a feed size not higher than 1200mm and a capacity of 1-1200t/h. It is generally used as the first and second crusher in graphite crushing production line, and it has two types of equipments for coarse crushing and fine crushing, and through the principle of crushing by extrusion, there is no need to worry about blocking of raw material even if it is large in particle size, and the crushing cavity is deep and there will not be any dead zone, which can enhance the throughput, and the optimization of the movement parameter makes the material start to be crushed in the upper part of the crushing cavity, and the lower part of the stroke can start crushing. The optimization of the movement parameters, so that the material in the upper part of the crushing chamber can start crushing, the lower part of the stroke is large, the crushing ratio is larger, plus the use of wedges to adjust the discharge opening, the finished product size can be adjusted, uniform size, plus the design of the flywheel, effectively reduce the vibration, more stable operation, while the motor seat and the host of the integration of the structure, so that the installation of the installation is simple, save space.

2.Impact Crusher

Impact crusher has a feed size not higher than 800mm and a capacity of 30-800t/h. As a secondary crusher, impact crusher adopts a new concept of crushing technology and utilizes impact energy to crush the material, which enters into the first, second and third impact chambers from big to small to repeat crushing until the material is crushed to the required size, and it adopts a heavy-duty rotor design, which gives it a larger rotating inertia, and the plate hammer has good impact resistance. In addition, the heavy duty rotor design gives it greater rotational inertia, and the plate hammer has good impact and wear resistance and keeps the discharge size stable. In addition, the optimized frame structure makes the connection strength higher, and the light weight and compact structure make it convenient for installation, maintenance and transportation.

We know that product quality is to ensure that the company continues to move forward on the basis of from understanding customer product requirements to drawing design, manufacturing, testing and inspection and even the finished product does not dare to have the slightest slack, every link is to strive for perfection, to play all efforts to make customer satisfaction. Welcome the majority of users at any time to click on the website customer service consulting, 24 hours online!