What are the models of 20 tons per hour crusher

Crusher, also known as stone crusher, is widely used in infrastructure, cement, chemical industry, metallurgy, transportation and other industrial sectors, for a variety of ores and large soft, medium and high hardness material crushing, processing into different specifications of stone, which models of crusher with a capacity of 20 tons per hour?

At present, there are about a dozen types of crusher equipment on the market, for the hourly output of 20 tons of processing capacity, can meet the requirements of the jaw crusher, hammer crusher, composite crusher, roller crusher and other equipment, there are a lot of models to choose from, the specific need to be based on the actual needs of the customer and the material situation to a reasonable choice. You can click on the website customer service to consult immediately.

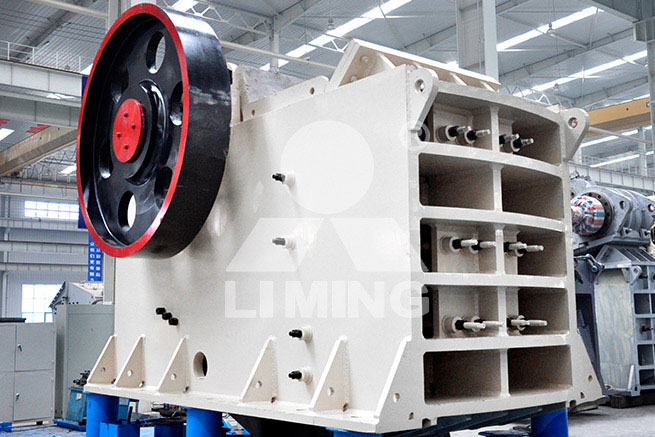

1. Jaw crusher can handle all kinds of hardness ores and large materials, with coarse and fine crushing, because of its deep crushing cavity, there will be no dead zone, the raw material size is not worried about plugging, while the wedge to adjust the discharge opening, the finished product size can be adjusted, uniform size, which will help the second section of the equipment crushing process, in addition, optimize the parameters of the movement, so that the material in the upper part of the crushing chamber can begin to crushing, the lower stroke is large, the crushing ratio is larger, and the motor is more than the crushing ratio, and the crushing ratio is more than the crushing ratio. The crushing ratio is bigger, meanwhile, the integrated structure of motor base and main machine makes the installation easy and saves the occupied space.

2. Hammer crusher is suitable for medium hardness and brittle materials, mainly relying on the impact of the hammer to crush the material, can be a finished product, join the modular design, through the replacement of the cavity type, adjust the coarse, medium and fine crushing, reduce the cost of 40% or so, the equipment has a compact structural design, occupies an area of less, in line with the small output, small batch operation requirements.

3. Compound crusher is suitable for all kinds of medium-hard and weakly abrasive materials, the main technical parameters of the optimization of the design developed into a new type of fine crushing/coarse grinding products, to achieve a single operation, the use of the principle of stone working principle, the crushing ratio of the degree of large, coupled with the setting of no sieve bars, mud-containing materials is not easy to clog the moisture content can be up to 8% or so, the overall efficiency to improve, because of the three-dimensional design, so the footprint is small.

4. Roll crusher is suitable for all kinds of medium and high hardness materials, the roller design, through the two rollers between the extrusion crushing, driving device are by two electric motors, kinetic energy more powerful, the same capacity to save 45% of energy consumption, and higher production efficiency, the surface of the rollers have uneven teeth, the use of new type of high-strength wear-resistant materials, energy loss is small, long service life.

We are able to provide you with high quality equipment and reliable technical support, welcome to click on the customer service consulting.

-

Which kind of mill is used to process the bicarbonate powder in the paint

-

Raymond machine dust collector bag should be maintained frequently