What are the complete sets of stone crusher equipment

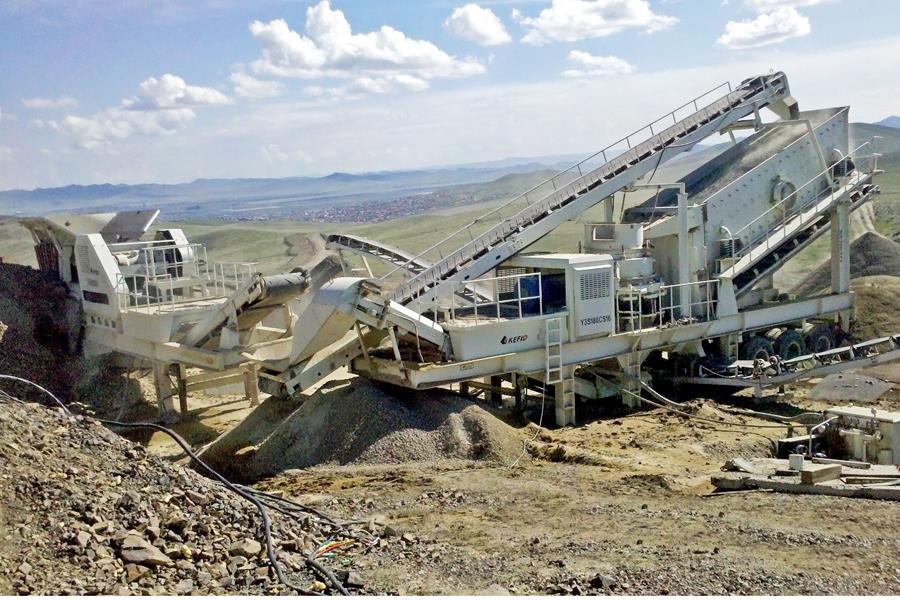

In today's building materials and mineral processing industry, stone crusher production line as an important support for infrastructure construction, and its efficient operation to enhance resource utilization and reduce production costs plays a crucial role. What are the components of a complete set of stone crusher equipment? How much does it cost to configure a stone crusher production line? Here is the answer for you.

Stone crushing production line is a series of equipment integration, aimed at large raw stone through multi-stage crushing, screening and other processes into different specifications of construction stone or mechanism sand. A complete stone crushing production line usually contains the following key equipment:

1. Vibrating Feeder

As the "throat" of the production line, the vibrating feeder is responsible for feeding the raw materials into the crusher evenly and continuously, ensuring the crushing process is stable and efficient, and reducing the blockage phenomenon.

2.Jaw Crusher

As the core equipment of coarse crushing stage, the jaw crusher, with its powerful crushing force and wide range of feed size (≤1500mm), can initially crush the large stone into smaller sizes, in preparation for the subsequent medium and fine crushing.

3.Medium and fine crushing equipment

According to the characteristics of the material and the requirements of the finished product, the middle and fine crushing link can choose cone crusher or impact crusher. Cone crusher is suitable for high hardness materials, with high capacity and good shape control; while impact crusher is excellent in handling soft to medium hard materials, providing better shape and size distribution.

4. Conveyor Belt

It connects the crushing and screening processes, realizing fast and continuous material transfer and improving the overall operating efficiency.

5.Vibrating Screen

Used for grading and screening, the crushed materials are sorted according to particle size, and the unqualified materials are returned to the corresponding crusher for re-crushing to ensure that the product specifications meet the requirements.

6. Sand making machine (if sand making is required)

For the production line that needs to produce mechanism sand, sand making machine is indispensable, which can further crush and shape the stone material after medium and fine crushing, and produce high-quality construction sand.

7.Sand washing machine

Wash the mechanism sand, remove impurities, and improve the cleanliness and quality of sand.

8.Dust removal and environmental protection equipment

In view of the increasingly stringent environmental regulations, equipped with efficient dust removal system and wastewater treatment facilities to reduce dust and noise pollution and realize green production.

As a large-scale machinery and equipment manufacturer integrating design, production and sales, OCP Machinery has won the recognition and praise of many users over the years with its exquisite technology, reliable quality and perfect after-sales service. If you are interested in our stone crushing line whole equipment, welcome to click customer service consulting, 24 hours online.

-

1000 tons per hour limestone crushing production line process flow

-

What are the uses of recycled aggregates from construction waste