1000 tons per hour limestone crushing production line process flow

Limestone is a commonly used raw material for crushing and sand making, and its production line is also more common, with a capacity ranging from 100 tons per hour to thousands of tons per hour. This article takes 1000t/h production line as an example, introduces the production line process flow and other details under this output for reference.

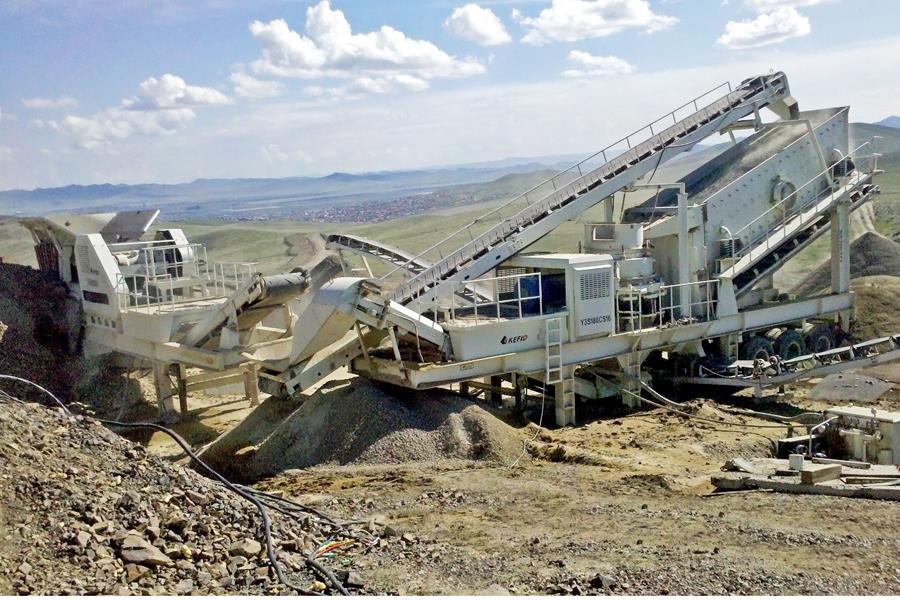

1. Take out the materials from the raw material warehouse and feed them evenly into the jaw crusher through the feeder, and the semi-finished products after crushed by the jaw crusher will be conveyed to the impact crusher through the belt conveyor to carry out secondary crushing;

2. The mixed aggregate obtained after secondary crushing is sent to the screen shop for grading and screening, and the large particles are sent to the fine impact crusher for crushing again, and then screened again to obtain different levels of finished particles, which are sent to the finished product warehouse by belt conveyor.

3. If the finished sand needs to be washed, a sand washer can also be configured for washing the finished sand. The bar feeder of the system also has the function of pre-screening, which can separate the fine particles in the raw materials in advance and directly enter the subsequent crushing equipment, and can also separate the dirt and debris in the raw materials as the discarded materials in advance.

Process characteristics: simple process, small footprint, large crushing ratio of the system equipment, high production efficiency, high output of finished products, high rate of sand, uniform distribution of finished products, good particle size, to meet the requirements of a variety of fields in the construction industry for the aggregate used.

Remarks: The limestone from different mines has different rock-forming conditions and variable material properties, so according to the specific rock properties, combined with the local aggregate market demand, we should design and develop a matching aggregate production process that meets the corresponding enterprise's requirements.

OCP Mining Machinery Company, for more than 30 years, has been focusing on the research and development and manufacturing of large-scale ore crushing and sand making equipment, mainly engaged in composite crusher, jawbreaker, hammer crusher, impact crusher, sand making machine, mobile station and other products. If you have any questions you want to consult, please feel free to click the website customer service, 24 hours online.

-

What are the uses of recycled aggregates from construction waste

-

What kind of equipment is used for construction waste recycled aggregate