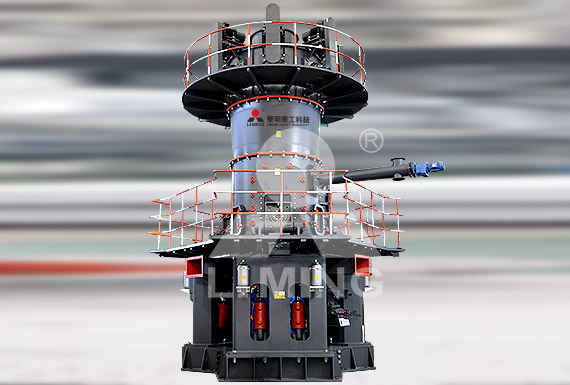

Ultrafine grinding mill is used in deep processing of mica ore

As early as the Song Dynasty in my country, there were detailed descriptions of mica ores. Mica is the collective name for all mica ores. It is rich in potassium, magnesium, aluminum, iron, lithium and other metal elements. It is widely used in industry and medicine because mica has It has good insulation, high temperature resistance, heat insulation, toughness and other characteristics. It is widely used in construction, electrical insulation materials, rubber and other industries. However, the use of the above various purposes requires the grinding of a grinding mill to achieve ultra-high performance. The fine grinding machine deeply processes the ultra-fine powder, which has better performance and higher usable value.

The production process of mica powder can generally be completed by a Raymond mill, but the particle size of the finished product processed by the Raymond mill is between 35 and 500 mesh. The final fineness of mica powder is mostly between 325 mesh and 3000 mesh, and the particle size is below 500 mesh. It can be ground by Aze Raymond mill, which has low cost and low investment. However, it is very difficult to re-grind fine powder with more than 500 mesh, resulting in low output, high energy consumption and low production efficiency. It is recommended that when purchasing grinding equipment, you should choose it according to different applications. If the fineness is not large, you can choose either Raymond mill or high-pressure mill. But if the fineness requirements are particularly strict, it is better to choose ultra-fine grinding mill. as well.

First of all, the ultra-fine grinding mill is a mill specially designed for the deep processing of ultra-fine powder. The processing of fine powder is more professional and targeted, with large output and high efficiency. It is the processing choice for all ore piles of ultra-fine powder. Micro powder grinding is perfect.

Secondly, it can be seen from the uses of mica ore that both industry and medicine use relatively large amounts of ultra-fine powder, and the requirements are strict. For example, industrial coatings and paints require a powder fineness of about 1,000 mesh, and pharmaceutical fine powder The required specifications are different, but the finer the powder, the better its performance. Therefore, from the perspective of the use value of mica ore, the practical value of choosing an ultra-fine mill for grinding is higher.

In addition, from the perspective of user production costs, when purchasing grinding equipment, the larger the utilization space, the better. In the field of mica ore deep processing, ultra-fine grinding mills are the inevitable choice.

Finally, we have been in the grinding industry for many years, and our experience tells us that ultra-fine grinding is the most popular choice for grinding and processing mica ores.

Although the fine powder particle size in the current grinding industry can reach several thousand mesh, it is still far from enough in terms of development. Ultra-fine powder grinding needs to continuously improve technology and develop to another level. The exploration and discovery of ore properties need to continue to break through. The original composition can be achieved, and the realization of all this research must be based on ultra-fine powder technology. Therefore, the future development of grinding technology requires continuous efforts in ultra-fine powder processing to achieve a breakthrough in micro-mill technology.

As for the specific price of the equipment, you can click on the website customer service consultation at any time to obtain a preferential quotation. We will arrange a dedicated person to receive you for an on-site inspection.

-

Jaw crusher to help roads and other infrastructure development

-

Industrial mill for agricultural construction continue to tap the potential of humic acid

-

Diatomaceous earth mill in agriculture and animal husbandry applications