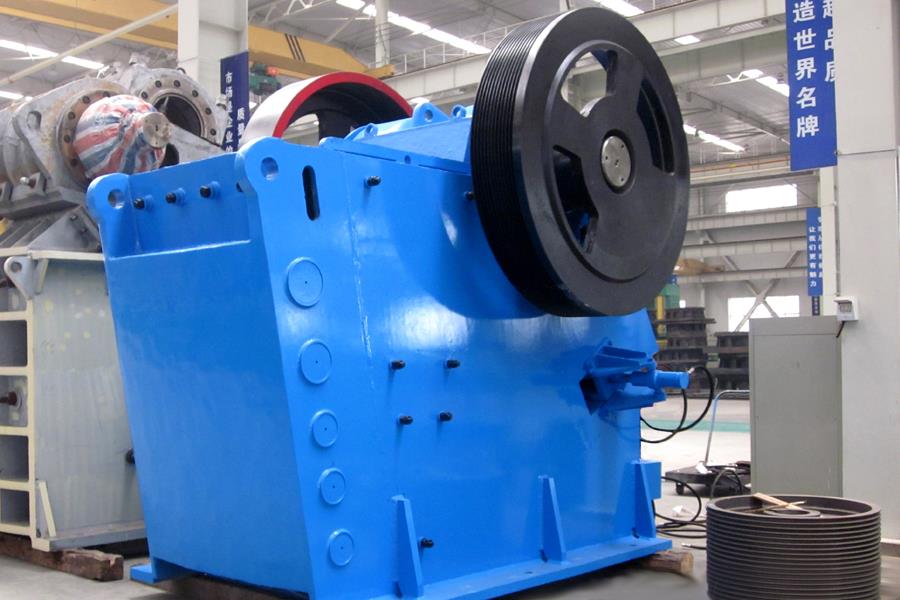

Jaw Crushing and Screening Machine

Jaw crushing and screening integrated machine combined with the market situation in recent years, the user's actual production needs, at first glance that it is just an ordinary equipment, but it is powerful lies not only applicable to crushing, it can also realize the feeding, screening, transportation and other links.

Usually consists of feeder, jaw crusher, circular vibrating screen, belt conveyor, centralized electronic control devices, except, including chassis, frame, generator set, etc., are all one-piece structure composed of a car, like a stone crushing production line, according to the needs of a flexible configuration, customized assembly, diversification of the choice of purchasing a machine, do not need to buy other equipment, saving a lot of investment.

1. Mobile and flexible, on-demand: Jaw crushing and screening machine is also called vehicle-mounted mobile jaw crushing and screening machine, which adopts the whole ship-shaped steel frame structure, low chassis, strong running stability, carrying semi-trailer, can be directly driven to the work site, the operation is timely and effective, convenient and quick, without the need for complex installation, ground pile setup operations.

2. Small footprint, handle multiple sites: modular assembly mode and folding feeder bin, hydraulic support guard, the overall footprint is small, each link of the equipment expansion and contraction, for the site is narrow, climbing, etc. are no longer talk about, to handle a number of sites, reduce customer operating costs.

Everyone in the purchase of equipment focus on different points, some people pursue the product appearance, some people pursue the cost-effective products, and this jaw crusher can meet the integrated jaw crusher and screening machine, integrated into the automatic control programming system, integrated intelligent design, in the control room can be realized in a number of operations of remote control, reducing the workload of the staff to save time, energy and money.

The design retains the V-shaped deep crushing cavity of the jaw crusher, which not only improves the feeding efficiency, but also enhances the processing capacity. Meanwhile, there are special electric motors and diesel generators, which can meet the normal and continuous operation under the complicated situation of sudden powerlessness or power outage, with low vibration, low noise, high efficiency and low energy consumption at the same time, and the finished stone material after treatment has less impurities, uniform and orderly, and the utilization rate is improved.

For environmental protection issues, the use of craftsmanship special air self-circulation system and fully sealed structure design, auxiliary dust collection, noise reduction devices, as well as on-site spraying devices, to strengthen the sealing of the body to control dust leakage, to avoid pollution problems, over the environmental assessment.

For such a jaw crushing and screening machine, are you moved? How much does it cost to invest in one? Overall the price is not expensive, because of its model variety, different equipment selection, the price is slightly different, you can click on the online customer service consulting, affordable one-step, there are sales managers for the provision of specific quotations, but also according to your needs, to help recommend the right type of equipment.