Heavy Duty Hammer Rock Crusher

Heavy-duty hammer rock crusher, combined with the development of the market, into the user's actual use of demand, the use of new production technology, integrated into the new concept of intelligent, PLC automatic control programming system to work, high degree of mechanization, the operation is more simple to sit in the operating room real-time remote monitoring.

At the same time can be a key to switch any mode of operation, can realize the start / stop, voltage control, current and other various operating conditions in the grasp, but also in a timely manner to make early warning of equipment failure, in order to remind the staff in time to repair, view, reduce manual work, save operating costs, accompanied by you refreshing the whole summer.

Wide range of application, large crushing ratio: heavy-duty hammer rock crusher in the design of the improved crushing method and crushing deep cavity, to achieve a multi-functional, suitable for crushing a variety of medium-hardness and brittle materials, such as granite, basalt and other rock materials and construction waste, subject to the influence of the moisture content of the material is small, and the crushing ratio is very large, can be crushed at once molding, higher yield.

Cost saving and reliable quality: Configured with standard energy-saving motor, the motor itself consumes less kinetic energy and heat energy, reducing unnecessary consumption, while the hammer head is made of super wear-resistant composite steel, and the liner plate is made of Bachmann alloy steel, which makes the whole machine wear-resistant and more reliable, saving the production cost in the later stage.

Realization of green operations: environmental protection is also a more popular feature of the heavy-duty hammer rock crusher, it is a strong overall sealing type, configured with dust removal devices and noise reduction devices, effective control of dust, noise pollution, in addition, the use of wear-resistant buffer layer design, not only to protect the machine body, but also to reduce noise.

OCP machinery manufacturers craftsmanship and wisdom of all kinds of sand and gravel equipment for more than ten years, there is a standardized heavy industrial plant, equipment production process is strictly controlled, pay more attention to details, to provide users with high-quality equipment, there is a spot for everyone to buy, for free consultation, while the equipment are sold in their own home, there is no intermediate redundant and complex links and costs, heavy-duty hammer rock crusher price is more affordable, you can click on online customer service consulting to understand the Specific offer.

-

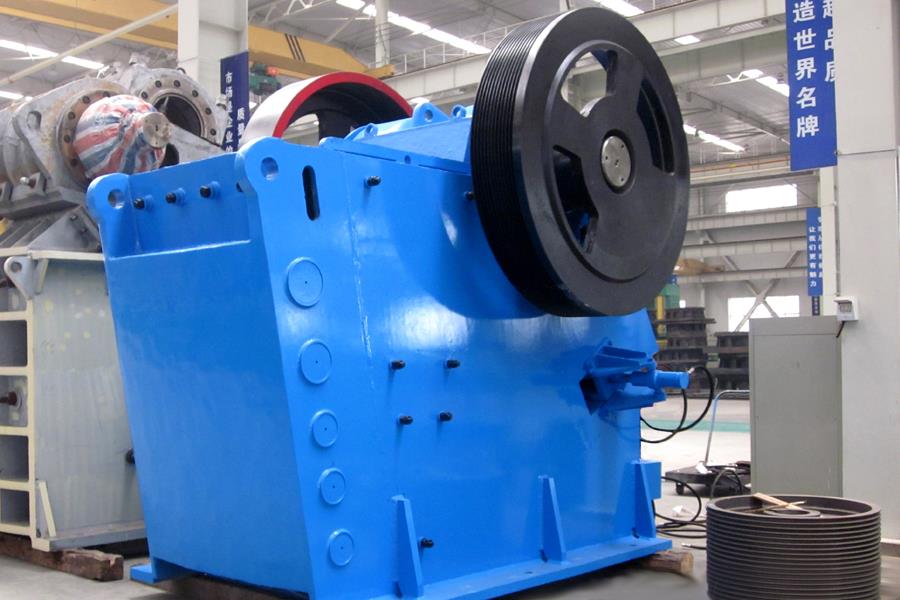

Jaw crusher with annual production capacity of 200000 cubic meters

-

All-in-one stone sand making machine is a mobile production line