Equipment needed for mechanism sand

Mechanism sand refers to the sand processed through the sand making machine and other ancillary equipment, the sand equipment mainly includes the crusher, sand making machine, feeder, vibrating screen, sand washing machine, conveyor and so on.

Process flow:

Large stone into the warehouse → feeding (vibrating feeder) → selection of coarse crusher (jaw crusher) → selection of second crusher (impact crusher / cone crusher / fine jaw crusher) → sand making and screening (impact sand making machine + vibrating screen) → cleaning and removing impurities (sand washing machine) → conveyor.

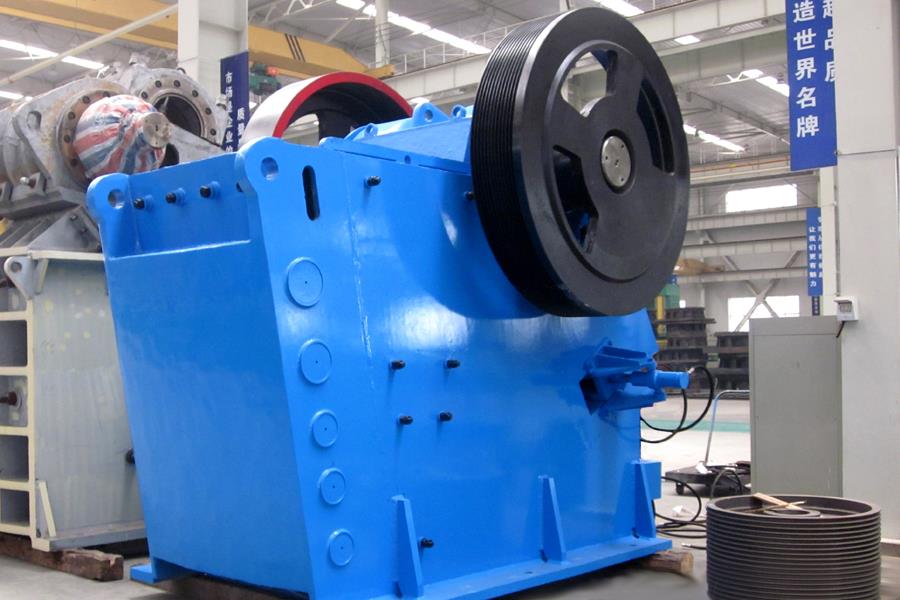

1. Jaw Crusher:

Through the extrusion crushing mode of operation, its cavity depth, no dead zone, raw material size is large without worrying about clogging, coupled with the optimization of the movement parameters, crushing ratio is larger, very suitable for crushing large stones, while the discharge opening adjustment is different from the traditional plug-board adjustment method, the use of wedges to adjust the discharge opening, particle size uniformity, but also reduce the labor intensity of the workers and downtime, the whole machine is durable.

2. Impact Crusher:

Adopting new concept crushing technology, the material is crushed by repeated impacts between the plate hammer and the impact plate, realizing the new process requirements of more crushing and less grinding, with strong rigidity of the machine, large rotor inertia, and convenient adjustment of the gap between the impact plate and the plate hammer, which can effectively control the granularity of the discharged material, and the processed finished product has high yield, is cubic, and has less powder, which is more in line with the standard.

3. Cone Crusher:

Laminar crushing cavity type and fixed-axis structure design, hydraulic motor to adjust the discharge opening adjustment is convenient to operate, crushing force, through the touch screen automatic control system to ensure the safe operation of the equipment, touch-screen operator interface, display real-time working status, all parts can be disassembled from the upper and side, hydraulic lubrication combined oil station, small size, simple wiring, small investment in the foundation, the rolling mortar wall does not need to be packed, replacement is quick and convenient.

4.Impact sand making machine:

Through the four-port impeller design, crushing cavity impact angle for improvement, through the amount of enhancement, large output, large discharge port design, material under the material smooth, effective prevention of material clogging, to avoid abnormal damage to the equipment, with a shaping effect, the finished product is relatively fine, mostly prismatic body, good particle size, taking into account the wear-resistant circumferential guard plate and the rock self-crushing point, the development of low-loss wear-resistant structure, reduce the wear and tear costs, hydraulic open cover device, Convenient maintenance.

If there is a need to enter the scene to understand the friends, feel free to contact, this side will arrange for you to visit the neighborhood customer site, as well as a later team of equipment commissioning, operation training, regular visits and a series of services. Click on the customer service immediately understand, 24 hours online.