Quarry equipment and facilities include what

Let's look at a practical case:

Processing raw material: basalt

Design output: 200 tons per hour

Feed size: ≤750mm

Discharge particle size: 12, 13, 24 stone

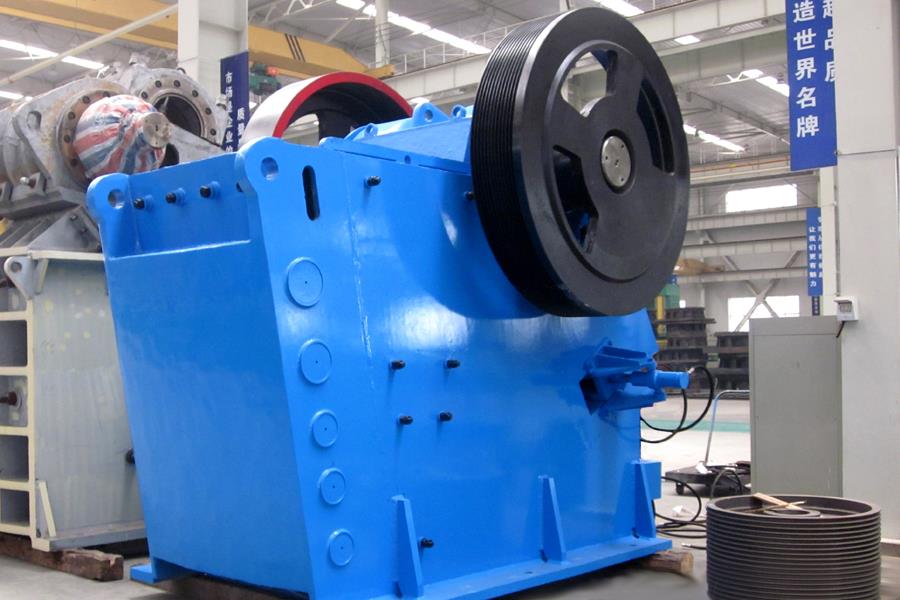

Equipment configuration: vibrating feeder + jaw crusher + cone crusher + vibrating screen + conveyor;

For quarry equipment, according to the current market understanding, there are about a dozen, hundreds of models, divided into small, medium and large, commonly used jaw crusher, cone crusher, impact crusher, impact crusher, hammer crusher, etc., the specific how to collocation, need to consider the output, feed size, finished product particle type / size, site, budget and other circumstances, customized for each customer.

1. Blasting equipment: rock drills, drilling rigs, air cannons and so on;

2. Transportation equipment: shovels, trucks, excavators, loaders, dump trucks, etc;

3. Environmental protection equipment: dust collector, vibrating screen sealing cover, sealing conveyor belt;

4. Quarry production line equipment configuration: vibrating feeder → jaw crusher → impact crusher / cone crusher → vibrating screen → impact crusher → vibrating screen → conveyor.

Crusher, mill and other equipment model types to choose more cumbersome and complex, in order to better help customers to solve equipment selection and other technical problems, our company set up a professional and technical customer service 24 hours a day for your service, click on the web page customer service immediately chat online.