Detailed explanation of the working principle of the grinding roller of the high pressure mill

Grinding roller is Raymond mill in the grinding parts, but also wear parts, in the grinding of the status of the pivotal, grinding roller wear on the output of the impact is very serious, in order to overcome this defect, technicians night and day, tireless exploration, development and finally found a solution, and then appeared in the high-pressure roller mill, the increase in output is how to achieve, high grinding roller working principle and what is it?

Before understanding the principle of high-pressure grinding roller, first look at the traditional Raymond mill is how to work, if from the mill's side profile view, scattered grinding rollers through the plum frame fixed together, linked to the spindle, the periphery of a circle is in close contact with the same material and the grinding ring, the spindle in the role of the electric motor, uniform high-speed rotation, and then the rollers with its circular motion, according to the principle of mechanics, in the rotating According to the principle of mechanics, the centrifugal force will be generated at the same time and act on the grinding ring, at this time, the shovel fixed in the ground shovel in the rotation at the same time to shovel up the material in the grinding chamber in the grinding ring, between the grinding rollers, so as to realize the grinding effect. However, in this process, Raymond mill wear parts will also have different degrees of wear, but the use of a period of time, grinding rollers, grinding roll thickness of less than 10mm, the gap between them increased significantly, can not play the role of grinding, declared obsolete, and so on replacement. In this way, every few months after processing the need for grinding rings, grinding rollers for new, time-consuming and laborious and the cost of a big increase.

High-pressure roller mill is to overcome this defect, in the grinding rollers to improve, from the longitudinal profile can be seen, high-pressure mill rollers and the outer host wall are more than a high-pressure spring device, because certainly think back to how to achieve such a device to increase production, extend the service life of the role of accessories. Careful users will find that the grinding chamber spring is installed in the grinding roller inside position, not above, from the mechanical point of view of analysis, when an object inside the force will produce an outward pressure, it is also under the action of this pressure to force the grinding roller to the role of the outward, with the grinding ring to maintain close contact at all times, in fact, the thickness of less than 10mm, in the high-pressure effect of the grinding rollers and the grinding ring can be tightly connected to achieve the role of the grinding. So don't underestimate this little spring, but the role is not to be underestimated.

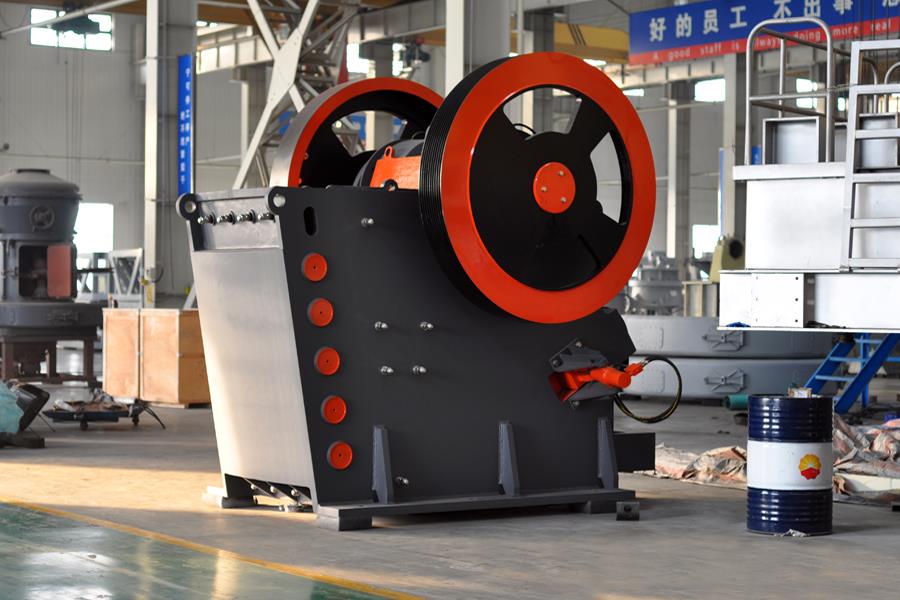

Crusher, mill and other equipment type type selection is more complicated and complex, in order to better help customers to solve the equipment selection and other technical problems, our company set up a professional and technical customer service 24 hours a day for your service, click on the web page customer service immediately chat online.

-

Raymond mill to improve the comprehensive utilization rate of mineral resources

-

Detailed explanation of the main role of silica raymond mill embodied in which

-

How to choose grinding equipment for processing silica powder

-

What are the uses of concrete after breaking it into machine sand with crusher