How to choose grinding equipment for processing silica powder

Silica hardness, high whiteness (up to 99.9%), the choice of mill in the milling process is very important to the quality of silica powder requirements, the choice of the right mill, not only can improve the performance of silica powder, and the use of equipment is not easy to fail, longer life. So how to choose the grinding equipment for processing silica powder?

1. First of all, consider the hardness of silica, choose the mill's hardness range should be in the 9 level or so, the traditional mill on the hardness of the general requirements of the 6 level or less, so it is not suitable for silica powder grinding and processing, the new mill - high pressure mill, Europe version of the mill processing materials are up to 9 level, and high yield, good efficiency, so this mill grinding out the high quality of the powder, fine and uniform. Europe version of the mill is now the grinding industry's advanced equipment, in the environmental protection and energy saving in this area has the international leading level, less dust, no noise, smooth operation.

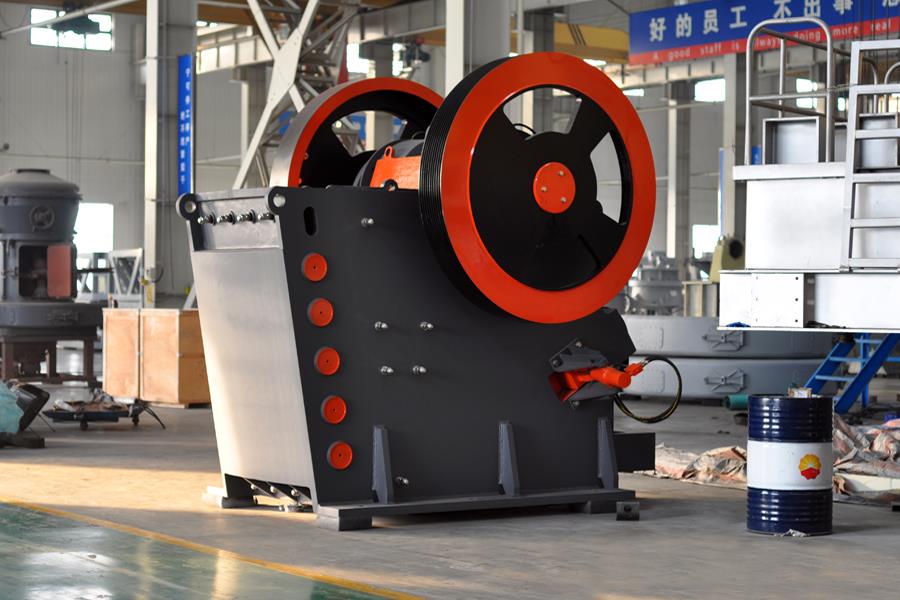

2. Secondly, the mill should be crushed by the jaw crusher before grinding, can also be equipped with other grinding, coarse grinding equipment, until the mill is suitable for grinding, so as to ensure the efficiency of the grinding process, but also to protect the quality of the finished product of the powder, because silica hardness, if the feed is too large for the European version of the mill on a certain degree of damage.

3. In addition, silica powder whiteness is very high, which is also the reason for the application of a very wide range of reasons, so the requirements of Baidu is particularly high, due to the mill material problems, more or less there will be a small amount of iron powder, and silica powder such as whiteness, iron content requirements for high materials, the slightest iron powder is not allowed, random OCP miner suggests that we can be equipped with a set of magnetic separator for magnetic separation to remove the iron in the powder, so the quality of silica powder can be obtained, and the quality of the powder can be improved. So the quality of silica powder can be guaranteed.

4. Finally, the grinding of silica powder is better according to different uses, some mills can be completed; some need a new type of milling equipment - European mill processing; there are also some fineness requirements are particularly high, it is necessary to be equipped with a micro powder mill or ultrafine mill to achieve; choose a good mill host and then equipped with the corresponding crushing, conveying, feeding device to complete the entire milling production line processing.

We are a professional production of crushing and grinding equipment source manufacturers, so the market price is more affordable, if you need to welcome to our offices around the consulting negotiation, visit the purchase. We have set up distribution offices in more than 130 countries and regions in the world, welcome to consult customer service to learn more, 24 hours online free consultation.

-

What are the uses of concrete after breaking it into machine sand with crusher

-

Characteristics of construction waste classification mobile crusher