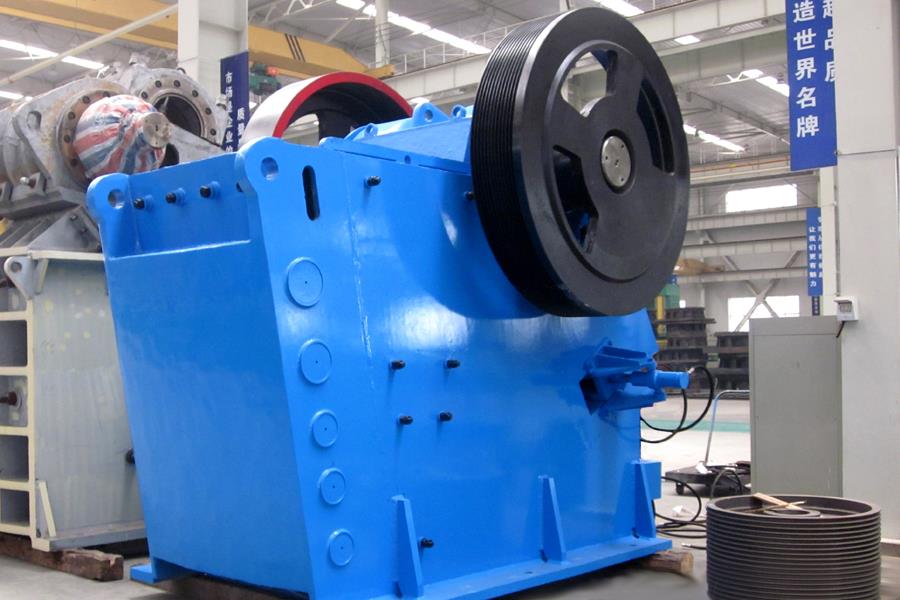

Crushing principle of stone crusher

Stone crushing refers to the process of using external forces to break large particles of material into small particles of material, crusher is the equipment that can complete the material crushing. The production power per hour and the corresponding crushing ratio are the main basic conditions to judge whether the crusher is a large-scale equipment, the crushing method of the crusher is different depending on the crushed material, please see the following article.

The material to be crushed needs to be subjected to a full range of extrusion in the crushing chamber of the crusher, the pieces of material impact each other or impact to the liner plate, resulting in a rapid transfer of material; the control of the material layer requires a certain degree of densification, from the inlet to the outlet of the crushing chamber, the crushing of the crushed material is gradually increasing. If you want to change the direction of the material pieces, you can use high frequency to make the material layer strong vibration, which leads to the material will produce shear and bending stress, this is the forced inner layer vibration crushing method. Large crusher, due to the material caused by a certain degree of compactness to meet the conditions of gradually increasing the crushing force, thus to a large extent to realize the selective crushing.

In a word, according to the different characteristics of the materials to be crushed, the crushing method chosen is not the same. Users want to achieve good crushing effect, need to choose the crushing method suitable for the material characteristics.

We are a professional manufacturer of crushing and grinding equipment, welcome to click on the customer service to learn more about the price of the equipment, production cases and other detailed information, 24 hours online free consultation.