Why choose jaw crusher for ore crushing

Ore refers to the mineral stones that have been extracted from mines and contain certain valuable minerals. Generally, after crushing, grinding and other processing, the ore can be used in metal, metallurgy, chemical industry, construction, railroad, highway construction units, cement industry and gravel industry and other engineering fields. Therefore, the crusher has an important position in the mining machinery industry, ore crushing why choose jaw crusher? The following is a detailed introduction for you.

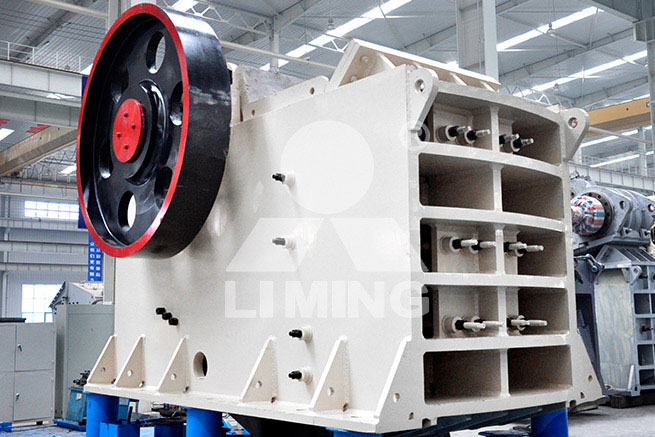

1.Introduction of Jaw Crusher

Jaw crusher is a highly efficient and energy-saving crushing equipment developed by our company with the successful experience of similar products at home and abroad. Large and medium-sized jaw crusher is one of our hot-selling products. Jaw crusher is mainly used for medium size crushing of all kinds of ores and large materials, and is divided into two kinds of coarse crushing and fine crushing. With complete specifications, this series of products is the preferred equipment for primary crushing.

2.Structure

The structure of the jaw crusher is mainly composed of frame, eccentric shaft, large pulley, flywheel, movable jaw, side guard, elbow plate, elbow plate; back seat, clearance screw, reset spring, fixed jaw and movable jaw, etc., of which the elbow plate also plays the role of insurance.

3.Working Principle

Jaw crusher crushing mode is curved extrusion, motor drive belt and pulley, through the eccentric shaft to make the movable jaw up and down movement. When the movable jaw rises, the angle between the elbow plate and the movable jaw becomes larger, which pushes the movable jaw plate to approach the fixed jaw plate, and at the same time, the materials are crushed by extrusion, rubbing, grinding and other multiple crushing. When the movable jaw goes down, the angle between the elbow plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the tie rod spring, at this time, the crushed material is discharged from the lower mouth of the crushing cavity, and with the continuous rotation of the motor crusher, the movable jaw is crushed and discharged cyclically, thus realizing the mass production.

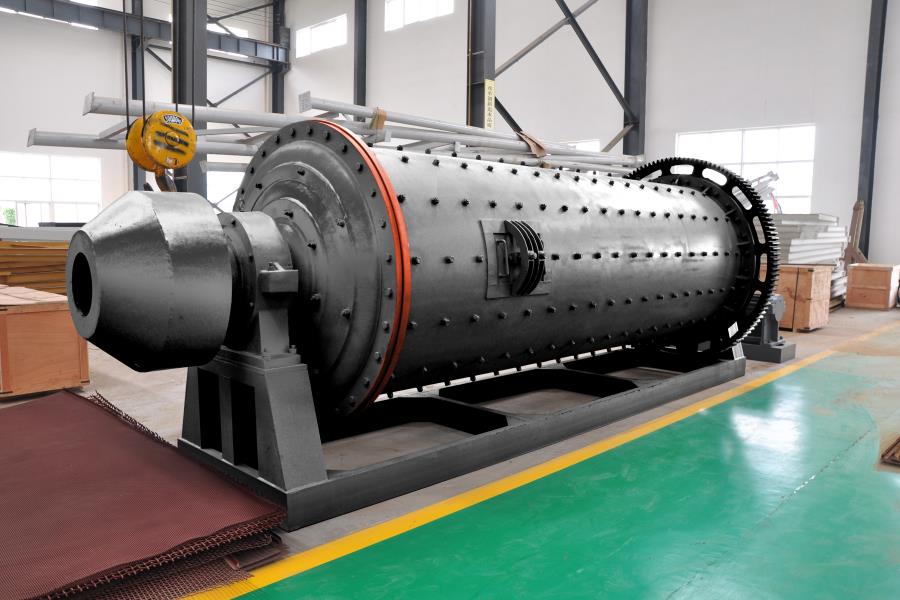

In the milling production line, because the material entering the mill can not be too big, so many raw ores need to be crushed by the jaw crusher, and then conveyed to the mill through the elevator for processing. In addition, in the stone production line and sand production line, because of the need to break the large stones into small pieces before the next step in the crushing process, so in the primary crushing (the first stage of crushing), also often use the jaw crusher, as for the use of coarse crusher or fine crusher, according to the actual raw materials to determine.

4. Manufacturer's strength

OCP wins the market with quality and is characterized by services beyond customer expectations, allowing customers to put into production quickly, quick return and no worries after sale. It has been widely acclaimed in more than 130 countries and regions in Asia, Africa, Latin America and Oceania. Quality assurance comes from attentiveness and details, and advantageous service comes from professionalism and dedication. Thank you for your attention and inquiry, and look forward to our long-term cooperation. Click on customer service to get a free consultation now, 24 hours online.