Which kinds of mill for power plant are there

Speaking of which kinds of mill for power plant? In fact, no matter what kind of model is really quite a lot, for example, according to the role of the process can be divided into desulfurization mill, coal crusher, etc., according to the type of mill can be divided into Raymond mill, high-pressure mill, European version of the mill, trapezoidal mill, coarse powder mill, etc., the following we come to understand in detail.

The reason why the mill can be stationed in the power plant market, is in the economic development and environmental protection awareness of the strengthening of the drive to achieve, the early thermal power plants on the grinding equipment is not much use, only need a simple jaw crusher, impact crusher and other crushing equipment for coal crushing can be directly to the next stage of the production of electricity supply, so for the coal crusher early just refers to the crushing equipment, why is the mill for the gradual entry into the production of the power plant Why is the mill gradually entering the power plant production, and become a specialized equipment for power plants? Then we have to consider from two aspects: one is the effective utilization of resources, and the other is environmental protection considerations.

1. Consideration of resource utilization:

Raw coal mining by the coal crusher simple crushed directly into the combustion furnace combustion, thermal power plants, the principle of power generation is the use of coal combustion in the thermal energy generated by the realization of the transformation of energy between the production activities for the power required, the amount of heat generated by the combustion of coal is the key to the utilization of resources in thermal power plants, and the combustion of coal needs to meet the three conditions: combustible, air, ignition point, coal as a combustible in the burning Coal as combustible material in the combustion of the ignition point can naturally meet, although the air to support its combustion of oxygen, but due to the early coal crusher crushed coal is mainly in the form of lumps, the contact area with oxygen is insufficient, combustion is insufficient, resulting in a low calorific value, the resource rate is not high, and the coal combustion of cinders and other waste products and more. And now the coal crusher crusher with the mill used together, the raw coal crushed and then sent to the Raymond Mill and other crushers within the grinding process into coal dust, through the pellet burner and other combustion devices sprayed to the combustion furnace instantaneous combustion, not only combustion is full of calorific value and more, and no residue, no solid waste.

2. Environmental protection consideration:

Coal combustion produces solid waste pollution of good land, water, etc., the most important thing is that coal combustion produces carbon dioxide, sulfur dioxide and other gases on the air pollution is serious, especially sulfur dioxide has a strong acidic gases is the main reason for the formation of acid rain, sulfur dioxide will exacerbate air pollution, suffering from heart disease and respiratory diseases of the most sensitive to this gas, sulfur dioxide also lies in the danger of it is often combined with the atmospheric Sulfur dioxide is also harmful because it often combines with atmospheric dust and enters the lungs of humans and other animals, or vaporizes spoons of sugar with water high in the air. Sulfur dioxide is also harmful because it is often combined with atmospheric dust, into the lungs of people and other animals, or in the air and water vapor combined into acidic precipitation, people and other animals and plants caused harm. Therefore, atmospheric pollution is typical soot-type pollution represented by soot and sulfur dioxide, and sulfur dioxide pollution should be highly valued.

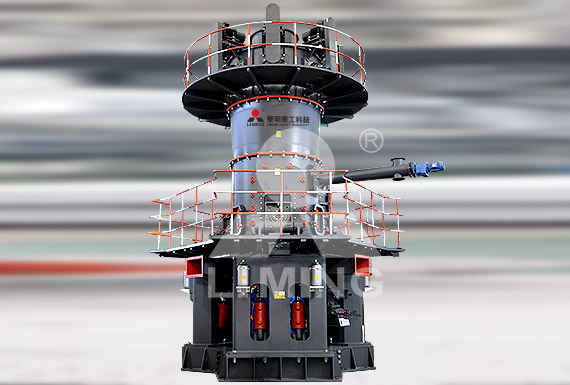

China is to coal as the main energy structure of the country, the production of sulfur dioxide is inevitable, in addition to combustion methods to control the production of sulfur dioxide gas, the world's more effective and mature technology is the power plant desulfurization process, the more sulfur dioxide chemical properties of the viability of the use of alkaline minerals, such as calcium carbonate, calcium oxide, etc., desulfurization of the powder, calcium carbonate powder to the tailpipe in the sulfur dioxide reaction occurs, producing Carbon dioxide, calcium sulfate, carbonated gas and sulfide gas than its harmfulness is much smaller, and the by-products produced calcium sulfate can be used as a by-product desulfurization gypsum to achieve that is to achieve the purpose of desulfurization, but also industrial gypsum resources of the double harvest, and the power plant desulfurization with the required calcium carbonate powder are required to industrial mills for grinding, lime powder fineness is not high more than about 300 mesh uniform powder, can be used for desulfurization process in the mill. Used in the desulfurization process mills such as Raymond mill, high pressure mill, European version of the mill can be.

Our company produces crushing and grinding equipment using advanced technology, carefully designed, focusing on quality. If new and old customers are interested in related equipment, welcome to visit our company at any time. We have production lines that have been put into use in many parts of the world, and we also have local offices that can take you on a site visit. Welcome to contact the website customer service, 24 hours online, to provide free consulting services!

-

Brief description of iron ore crushing and grinding mill and beneficiation process flow

-

Investment in powder processing plant storage and transportation link notes

-

Diatomaceous earth mill in the development prospects of urban wastewater treatment