What are the ferrosilicon crushing line equipment

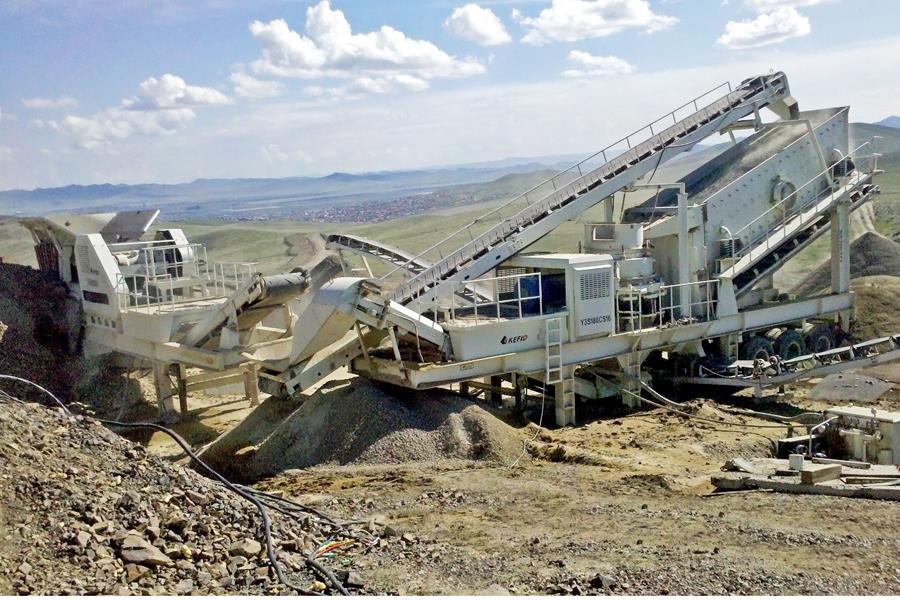

Ferrosilicon is the iron alloy composed of iron and silicon. Ferrosilicon is an iron and silicon alloy made of coke, steel chips, quartz (or silica) as raw materials, smelted by electric furnace. In the actual production line these ferrosilicon must be crushed first, and then processed to finalize the processing into the desired finished product, so what are the ferrosilicon crushing production line equipment?

Ferrosilicon crushing production line equipment more, here for you to introduce the following kinds of equipment:

1.Jaw crusher

Feeding size: can feed materials below 1500mm.

Discharge size: Adopting wedge to adjust the discharge opening, which can be adjusted between 10-350mm.

Hourly output: 1-2200t/h.

Advantages: Jaw crusher adopts deep v crushing cavity, processing no dead angle, large processing capacity, the overall hourly output of 1-2200t/h; optimize the overall movement parameters, the material in the upper part of the crushing cavity began to crushing, in the crushing cavity of the lower part of the stroke is larger, greater than the crushing ratio; the entire base of the machine is made of wear-resistant cast steel structure, in the process of production run more smoothly.

2.Cone Crusher

Feeding size: capable of handling raw materials less than or equal to 560mm.

Discharge granularity: the discharge is well adjusted, and the finished product can be adjusted between 3-60mm.

Hourly output: about 10-2181 tons per hour.

Advantages: Cone crusher adopts extrusion crushing method, which can effectively reduce the dust content and needle flake content in the production process; less abrasion and long service life of wearing parts in the process of handling ferrosilicon; meanwhile, it adopts the hydraulic cavity clearing system, which reduces the downtime, and it can choose different cavities according to different needs, which can better adapt to the user's needs, and at the same time, the full-automatic control system of PLC+touch screen ensures the safe operation of the machine. operation.

3.Roll Crusher

Feed size: can handle raw materials less than or equal to 30mm;

Discharge size: adjustable range 2-10mm, mainly used for secondary or tertiary crushing;

Hourly output: about 5-110 tons per hour;

Production advantages: ferrosilicon roller crusher, also called double roller crusher, rely on the squeezing force of the rollers to crush the ore, small size, large crushing ratio, low noise, simple structure, easy maintenance; in the overall production process is almost no wearing parts; small equipment size, large crushing ratio (5-8), uniform particle size, low over-crushing rate, the driving device are by two electric motors, kinetic energy is more powerful;

Ferro-silicon crushing production line full set of equipment prices in the hundreds of thousands to millions of dollars, the specific price is still based on the construction of the equipment and model parameters to determine; want to buy reliable quality, price concessions manufacturers of equipment, welcome to consult the website customer service, we can not only provide you with one-on-one technical engineers for your needs to answer your questions and solve the problem, design the production line, but also customize the production line equipment and training for you! Related technical personnel, now come to the online consultation can also get a special offer belongs to you.Customer service 24 hours online.

-

What kind of materials is wolf tooth crusher suitable for crushing

-

Choose roll sand making machine to start a small sand making plant

-

Can cement block be used as stone after breaking and what kind of stone crusher is used

-

Which type of sand making machine is good for gravel sand making