What are the cooling systems in the grinding production line

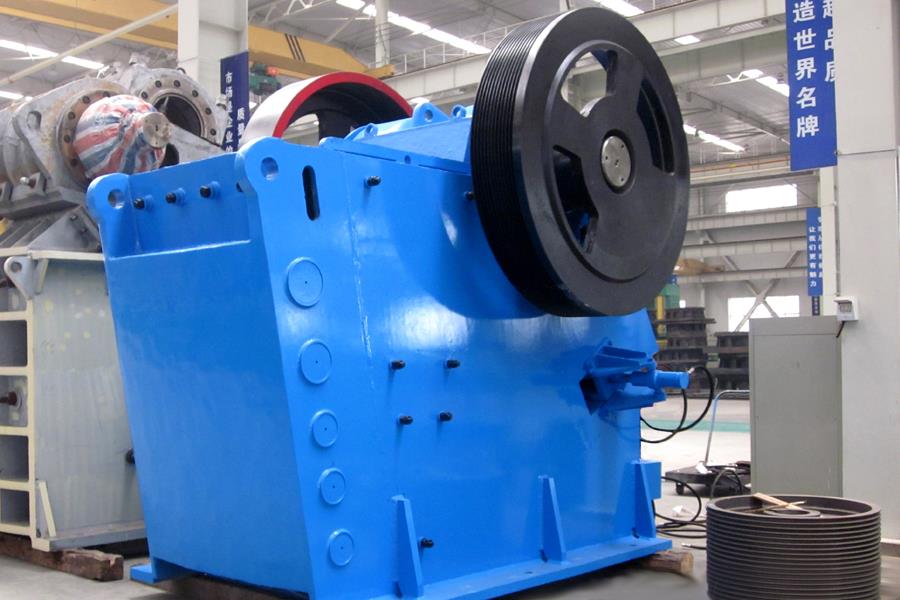

Grinding production line belongs to the mining industry more common set of production equipment, such as power plant desulphurisation grinding production line, gypsum production line, calcite production line, etc., in fact, Raymond mill is the most widely used, however, a variety of supporting grinding equipment in the process of processing there will be a common problem - heat, due to the mill's principle of working for the grinding structure, so the heat is unavoidable, but how to control and prevent the high heat burning machine is still necessary. But how to control and prevent excessive heating and burn the machine is still very necessary. Here we look at the milling process in the cooling system what?

The main cooling system in the mill production line has two aspects: one is the fan bearing box cooling, and the other is the thin oil circulation lubrication cooling system.

Grinding screening, conveying by the air volume to complete, the air volume generated by the fan, and the rotation of the fan is driven by the click, between the motor and the fan by the spindle, bearings connected to the spindle in the bearing rotation process will produce a large amount of heat, if you can't dissipate it in time will burn out the bearings, resulting in the fan can't rotate, the whole set of milling production line will be in a paralysed state, the powder can't be transmitted, so the cooling of the fan bearing is Therefore, the cooling of fan bearings is very important. Grinding industry after a long period of development, Raymond mill manufacturers in the fan blade wheel and the host bearing between the outside will add a fan bearing box, which is equipped with cold water, so that the bearing in the process of rotation of the heat generated by the water can be well dispersed, which is why the mill needs to add water in the process of work.

Thin oil circulation lubrication system, on the one hand, play a role in lubrication, on the one hand, play a role in cooling the bearings to the mill host, in its Raymond machine does not have this device, so the heat dissipation effect is not very good. Now the new mill are equipped with word lubrication system, thin oil in the flow of the process, the bearing parts of the heat generated also take away, so that the heat is not uniformly concentrated in which point and burned equipment.

The above two devices on the milling production line play a good role in cooling, with the development of science and technology, the milling industry is also constantly innovating, changing the original production technology, the future of the new Raymond mill productivity, service life and other aspects of performance are bound to improve. If you are interested in related equipment, consult the website customer service, 24 hours online.

-

Fan bearing box is the cooling expert in the milling production process

-

Users and Raymond mill manufacturers need to do a good job with what work