Several commonly used bentonite grinding machine

Bentonite Raymond machine: suitable for materials below 9.3 level, the fineness of the finished product between 30-425 mesh, the enduring grinding machine, stable technology and excellent quality, the most important feature is the affordable price.

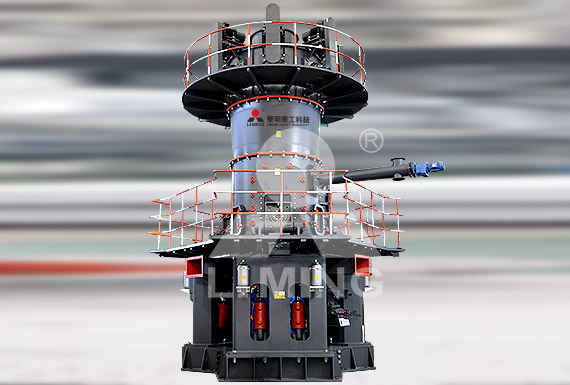

Bentonite roller mill: grinding technology has been slightly improved, compared with the Raymond machine output is greater, the same range of materials used, the fineness of the finished product is more uniform and meticulous, and the finest powder up to 1,000 mesh, belonging to the current market's best-selling grinding equipment.

Bentonite European mill: the current grinding market advanced equipment, the introduction of foreign advanced technology combined with the domestic strength of the comprehensive development, the quality of the finished product, the production efficiency has a strict pursuit of the goal.

Bentonite ultrafine mill: bentonite special industry use only, the dosage is small, but the focus of the future development of the milling market direction.

Realize the value of bentonite applications must be ground with the help of industrial mills reproduction, with the development of bentonite so that a long history, the original is only as a detergent, and then the structure of the performance is constantly being discovered, the application range is more and more extensive, the mill is the internal structure of the material to explore, and found that the synthesis of the new material is the main machine, not only in the bentonite minerals of great significance in the other non-metallic minerals are also important in practice! For example, potassium feldspar, limestone, dolomite, kaolin, talc, gypsum and so on. If you are interested in bentonite mill, welcome to click on the website customer service to learn more about equipment details, 24 hours online, free consultation.