Rock sand making equipment and its price

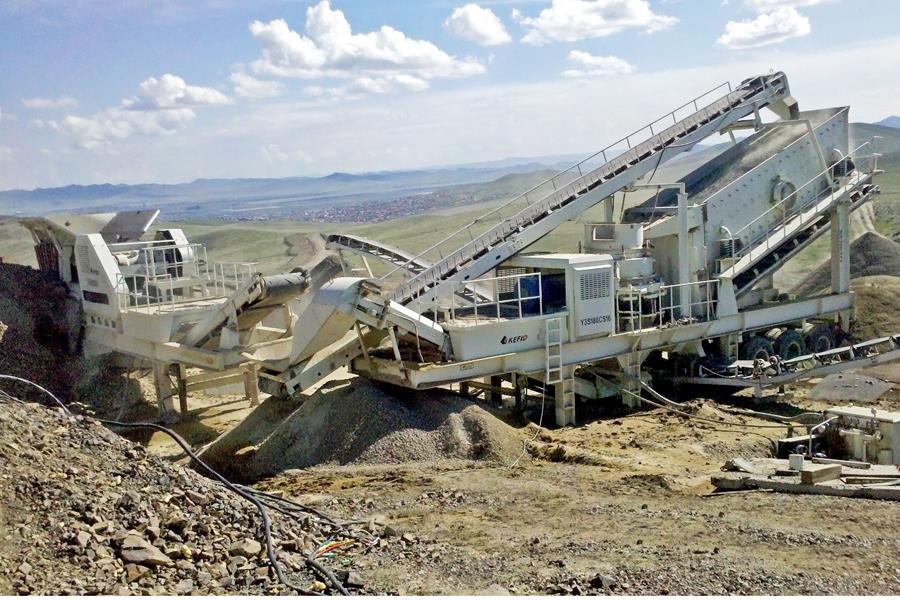

The method of using rock sand making equipment to process and handle various common rocks to make them meet the standards of construction sand to replace natural sand is loved by the sand and gravel industry. Today we will give you an introduction to the rock sand making equipment and its price.

To get the mechanism sand that can replace natural sand, rock sand making equipment is very important. Rock sand making equipment can be made according to the user's production needs, so that a variety of common rocks are crushed into a mechanism of sand in line with the standards of construction sand, so as to replace the natural sand, and relatively speaking, the mechanism of sand raw material mining costs are greatly reduced.

Common rock sand making equipment include jaw crusher, cone crusher, impact crusher, hammer crusher, impact crusher, etc. These equipments play their own roles in rock sand making production line and co-operate with each other to make sand and gravel to meet user's production.

Jaw crusher is commonly used in the rock sand production line in a section of the crushing, cone crusher and impact crusher is more common in the second section of the crushing equipment, heavy hammer crusher is more special, in the rock sand production line can be against the two sections of the crushing, because of the equipment's feed size is relatively large, but the feed size is relatively small, basically can make the crushed stone a moulding, no need to carry out the second crushing, reduce the workflow, save investment costs, and the finished product granularity of the sand and stone to meet the user's production. It saves the investment cost, and the finished product grain shape is also better. Rock sand production line, the above equipment according to the size of the crushed raw materials and production needs to decide whether to need, but I think the impact crusher is necessary. If you want to make sand from rock crushing, the size of the finished product is generally smaller, and the discharge size of the impact crusher is generally around 0.55mm, the finished product is fine, and the equipment also has the function of shaping, and the finished product has a better grain shape, which is a very good rock sand making equipment.

Note: The feed size of the impact crusher is relatively small, generally not more than 60mm, so if you encounter larger rocks, you still need to match the above crushing equipment.

The price of rock sand making equipment is generally a matter of concern to users, so how much is rock sand making equipment? Understand the sand industry should know, the market rock sand making equipment models more, each of the output, in and out of the material size, energy consumption, area, etc. There will be differences, so the price will be different, here can not give a specific price. You can according to your production needs, click on the website customer service online free consultation, will docking technicians to recommend the right model, and inform you of the specific price, but also to get a discount offer.