Raymond mill technical performance to be improved places

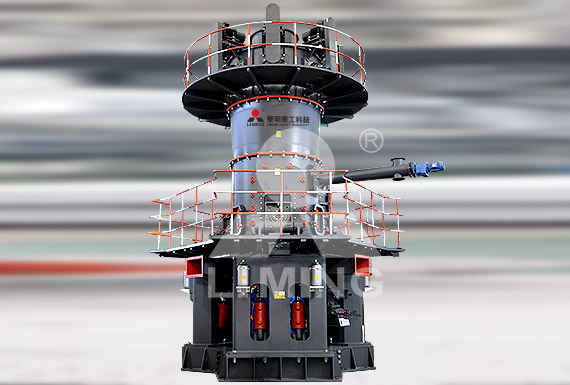

Industrial Raymond mill, although mainly used for powder grinding, but appropriate changes in its production structure can achieve many different effects, OCP has been specializing in the development of grinding equipment for many years, more than one grinding equipment, large and small, the new European version of the Raymond mill is the company's patented equipment, greater output, higher efficiency, environmental protection and energy saving effect is better, OCP has always been adhering to the service to meet the production needs of customers! OCP has been adhering to the customer service, to meet customer production needs for the development concept, in the milling equipment to continuously improve and innovate, from the early drive Raymond mill to the new Raymond mill, and then to the high-pressure mill, the European version of the mill, such as new mills, and for the production of ultra-fine powder grinding three-ring medium-speed mill, ultra-micro-powder mill, etc., there is a demand for the market, OCP's goal is to continue to go beyond the present, from the actual needs of each customer, and the practical implementation of the mill to each of the performance.

Where is the technical performance of Raymond mill to be improved?

1. Mill output to be improved, grinding output has been improved, but want to meet the production requirements, the output of the equipment must also increase the improvement efforts, all-round more degree of thought.

2. Finished product quality, fineness, the new Raymond mill finished product fineness uniformity, fineness currently up to 3000 mesh or more, in the field of ultra-fine powder processing is an important direction of development.

3. Grinding equipment adaptability, such as material hardness, humidity, etc., mining new wear-resistant materials, the design of the internal drying system can expand the use of the mill to reduce the production process.

4. Grinding production line automatic control ability to be improved, reduce human resources investment, high machining efficiency, excellent quality, uniform specifications of the finished product, the automation of the production process is the focus of the development of various industries.

5. Environmental performance improvement, environmental issues are still intensifying, so the production process causes pollution source equipment control is more stringent, green energy-saving equipment is the ultimate goal of economic development, but also always strive to work in the direction.

We are a professional manufacturer of crushing and grinding equipment, welcome to click on the customer service to understand the price of equipment, production cases and other detailed information, 24 hours online free consultation.

-

Construction Waste Recycling Disposal Road is Tough Where Should We Go

-

How to realize the sieving of sand and gravel impurities in bentonite grinding mill

-

Mill sealing is an important basis for judging the quality of excellent

-

Whether heavy calcium powder mill and calcium hydroxide powder mill is the same kind of equipment