Raymond Mill Accessories Overview

When it comes to Raymond mill accessories, the first thing that comes to mind may be the important part of the grinding rollers and grinding rings, in fact, there are hundreds of kinds of accessories that make up the milling equipment, from the big shells, silos, small bolts and nuts, and even some accessories in time to grind industry personnel can not be called on the name of the mill accessories in the end what are the parts of the composition of the mill? What is the appearance? What is the role? How is the service life?

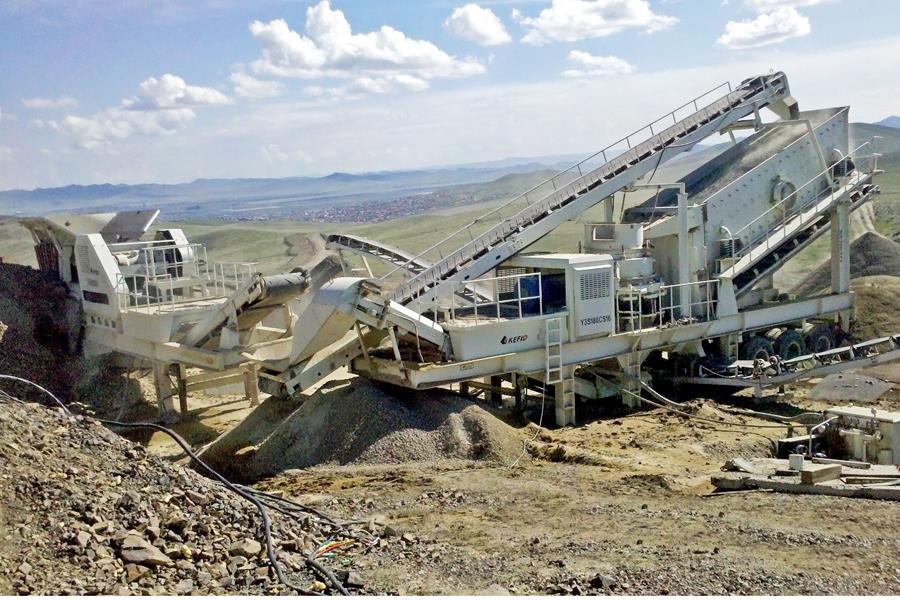

Grinding production line structure: from the appearance of the production line can be clearly distinguished from the mill machine by the jaw, bucket elevator, silo, vibrating feeder, host (grinding part and screening part), fans, pipes, powder collector, dust collector, etc. These components are from the appearance of the judgement, and most of the Raymond machine accessories hidden inside the mill, not easy to find, for example: mill rollers set on the cover, shovel frame, liner bushings, mill accessories, mill accessories, mill accessories, and so on, the mill is not easy to find, such as: mill rollers set on the cover, shovel frame, the lower plate, the liner bushings, the mill accessories, and so on. Lower plate, liner bushings, springs, spring pull shafts, air duct guard, shovel blade, shovel seat, gaskets, sealing gaskets, hinge seat, hinge seat cover, grinding rollers, mold stretcher shafts, grinding roller hanger, grinding rollers, grinding ring, PTFE pads, small bevel gear, blade, gland, gland nut, and so on, hundreds of parts and components combined. The following figure is a simple internal structure of the mill, today we will find a few typical parts to introduce its design principle, material composition and main role.

1. Grinding roller grinding ring, which we all know better, material high manganese steel wear-resistant material, casting and become, is the main grinding mill, but also wear parts, grinding roller assembly structure is shown below, the grinding roller due to long-term grinding work, wear and tear faster, in order to avoid wear and tear can be rebuilt structure or timely maintenance maintenance, such as the new high-pressure raymond mill mill rollers using high-pressure springs until, to a large extent, to improve the yield, and the wear of external forces under the wear of rollers, the wear of rollers. The wear and tear of the rollers under external forces can still continue to work also improves the service life of the wear parts of the grinding rollers and rings.

2. Shovel knife in the grinding process is the main carrier of materials, the material will be just right to the grinding rollers between the grinding ring for grinding, shovel knife relative material requirements are wider, but wear resistance in the quality considerations are also very critical, the initial shovel knife and grinding disc connected to the integrated structure design, once damaged need to be replaced together with the disc as a whole, the cost is high, large cost, replacement and maintenance is inconvenient, and now the new Raymond machine shovel knife is designed alone, consistent Damage can be directly replaced, the European version of the Raymond mill more curved type design to make the amount of bearing material is larger, higher yield, in addition to explain that the number of shovel knife grinding rollers are determined by the specified type of mill, and shovel knives and the number of grinding rollers to maintain the same.

3. Bevel gear transmission device, gear transmission is not every mill, it is connected between the reducer and the host, to achieve the role of mill speed deceleration, gear transmission on the lubrication requirements are strict, different models of mills lubricant selection is also stipulated, the gear is the channel for the transmission of kinetic energy, the transmission effect is directly on behalf of the milling equipment production results.

4. Grinding roller shaft and bearings, connected between the grinding roller and the plum blossom frame, is also an important transmission device, bearings and gears compared to the more damaged, has occurred wear, holding and other failures, due to the limitations of the working environment, Raymond machine bearing parts on the sealing requirements are very high, such as gaskets, oil seals, and other sealing measures, in order to prevent dust from entering the impact of the bearing transmission or lubricant contamination and other issues.

5. Rubber bushings, gaskets belong to similar role parts, play a role in shock absorption and wear, they are also one of the few soft materials in the milling production line, to protect the bearing frame and their parts have a good effect.

6. analyzer, fan blades, respectively, installed in the analyzer, fan inside, play the role of rotating powder selection, these parts are not easy to wear, but with the working time will also appear wear and tear problems, fan blade wear or abnormal rotation affects the transmission of the whole machine air volume, analyzer as a finished product qualification inspection agency, if the blade wear is serious quality of the finished product will be affected, the finished product particles will be too coarse and other issues.

Components of the grinding process is very much, the above is a few more important and common accessories, these parts have production due to various reasons for the risk of damage, especially grinding rollers, grinding rings, shovel knives, bearings, wearing parts replacement can be in the plant standby a copy of the blade, rubber sleeve, etc., low chance of damage, can be appropriate amount of spare parts, such as the other gland, nut, spring pull shaft, etc., almost no damage can be accompanied by the mill has been used, but no matter which Raymond mill process, the analyzer as a finished product inspection agency, if the blade wear serious impact on the quality of the finished product, there will be coarse particles and other problems. But no matter what kind of Raymond mill accessories, high or low price, are an important part of the grinding equipment, one is indispensable.

Raymond mill powder equipment accessories replacement instructions:

1. The choice of accessories is the key, there are some differences in the size of the accessories of different manufacturers, you need to verify the size of the purchase, it is recommended to better order from the original manufacturer.

2. Accessories should be installed in the correct removal and installation of accessories, otherwise it will affect the performance of the mill.

3. In the process of dismantling, the discharge of parts should be regular, gently take and put, especially the precision parts such as grinding rollers and rings.

4. Pay attention to cleaning and lubrication when replacing some parts, such as bearings and gears.

OCP Mining Machinery Company, for more than 30 years, has been focusing on the research, development and manufacture of large-scale industrial grinding, ore crushing and sand making equipment, mainly engaged in Raymond Mill, High Pressure Mill, Grinding Mill, Compound Crusher, Jaw Crusher, Hammer Crusher, Impact Crusher and other products. If you have any questions want to consult, please feel free to click on the website customer service, 24 hours online.