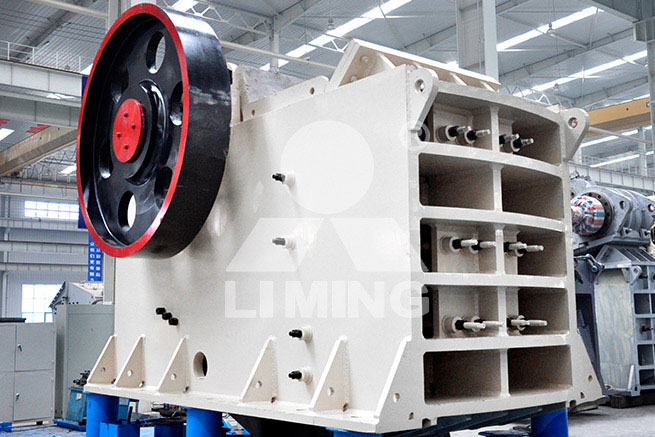

PE Jaw Crusher Features and Working Principle

Technical Specification:

Jaw crusher is used in the first process of crushing various minerals and rocks, it can process all kinds of ores with compressive strength not higher than 320MPa to medium size at one time, often together with cone crusher, impact crusher, sand making machine and so on to form a complete set of sand and gravel production line, which is widely used in the fields of mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and so on.

Application scope: sand and gravel quarry, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebbles, granite, basalt, iron ore, limestone, quartzite, pyroxene, iron ore, gold ore, copper ore, etc.

Outstanding Advantage:

Optimized deep-cavity crushing, digital analysis of the operation of each component, forging billet processing of heavy eccentric shaft, high manganese steel jaw plate and high grade cast steel movable jaw assembly, the crushing efficiency is greatly improved, the energy saving of the single machine is 15%-30%, the stability is higher and the service life is longer.

Under the basic principle of compound pendulum type, the structure is streamlined, the crushing capacity is strong, and it is easy to operate and overhaul; the unique centralized lubrication system, the lubrication is faster, and the maintenance workload is small.

Gasket-type discharge adjustment device, discharge adjustment range, flexible use, can meet a variety of customer processing requirements; low noise, can be matched with dust removal equipment, in full compliance with national environmental standards.

Working Principle:

Jaw crusher is mainly composed of frame, eccentric shaft, big pulley, flywheel, side guard plate, elbow plate, elbow plate back seat, gap adjusting screw, reset spring, fixed jaw plate and movable jaw plate and so on.

The crushing mode of the jaw crusher is curved extrusion type. When the jaw rises, the angle between the elbow plate and the movable jaw becomes larger, which pushes the movable jaw plate to approach the fixed jaw plate, and the materials are crushed through the extrusion, rubbing and grinding between the two jaw plates; when the movable jaw goes down, the angle between the elbow plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the tie rod and the spring, and the crushed materials will be crushed through the lower jaw cavity under the action of gravity. Under the action of gravity, the crushed material will be discharged freely through the outlet at the lower part of the jaw cavity. With the continuous rotation of the motor, the movable jaw does periodic crushing and discharging to realize mass production.

If you are interested in our products, or you want to base our production site visits, please contact the site customer service 24 hours for you!