Limestone powder production process and investment costs

Limestone is an important processing material in many construction industries and industrial manufacturing industries. After limestone is ground into fine powder, quicklime can be used for desulfurization in power plants, and slaked lime can be used for preparing various kinds of cements, lime slurry, lime paste, paints and so on, which are widely used.

Limestone powder production process

Limestone is dropped to the belt conveyor through the funnel at the bottom of the silo, and then sent into the Raymond mill for grinding. As the grinding roller rolls tightly on the grinding ring under the action of centrifugal force, the material is shoveled up by the shovel knife and sent to the middle of the grinding roller and the grinding ring, and the material is crushed into powder under the action of grinding pressure. The material is broken into powder under the action of grinding pressure. Under the action of blower, the powdered material is blown out and graded by the grader above the mill. Classifier is composed of radial radial bladed wheel and transmission device, bladed wheel driven by the transmission device to a certain speed rotation, the coarse particles in the airflow back to the mill, fine powder with the airflow through the wind sieve sent to the cyclone separator, so the classifier plays a screening role. Adjusting the air volume or changing the rotational speed of the blade wheel, you can freely adjust the particle size of the powder. The cyclone separator separates qualified products from air, and the finished products are transported to the finished products warehouse through the bucket elevator and then by the pipeline, while the air flow is returned to the blower for recycling by the return air pipe.

How much is the investment cost of the whole set of limestone grinding equipment?

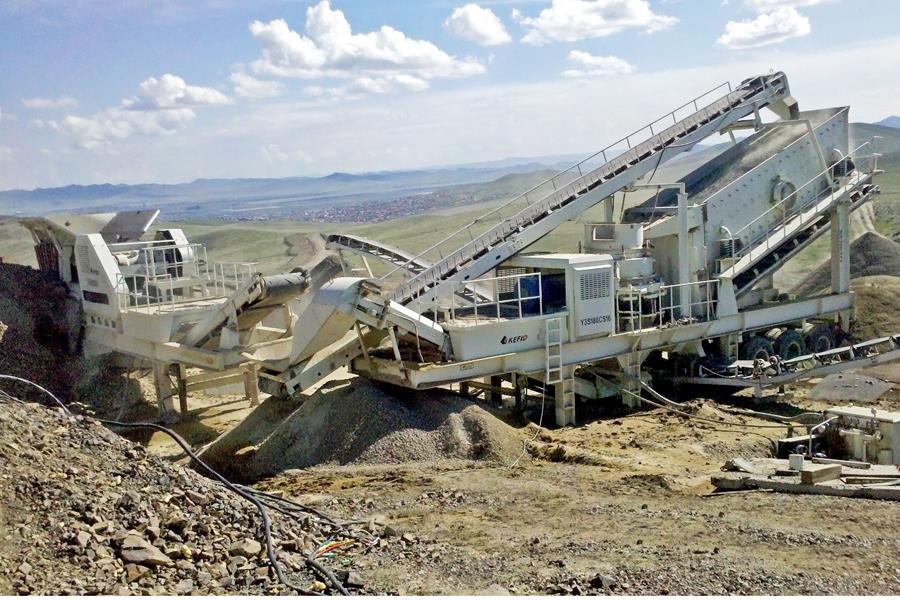

Limestone grinding production line uses equipment such as jaw crusher, impact crusher, Raymond mill, auxiliary equipment such as bucket elevator, vibrating feeder, and some dust collector, pipeline device, etc. Different production needs, the configuration of the program are different, the investment cost will have a big difference, the choice of different types of equipment, the price is naturally different, there is no a specific value here. professional crushing and grinding equipment manufacturer, with rich production experience, has provided many users with suitable production line configuration.

You can click on the online consultation, explain the production requirements, will be docked professional technical staff will configure specific programs for you, provide quotation information, dedicated to your service. 24 hours online.