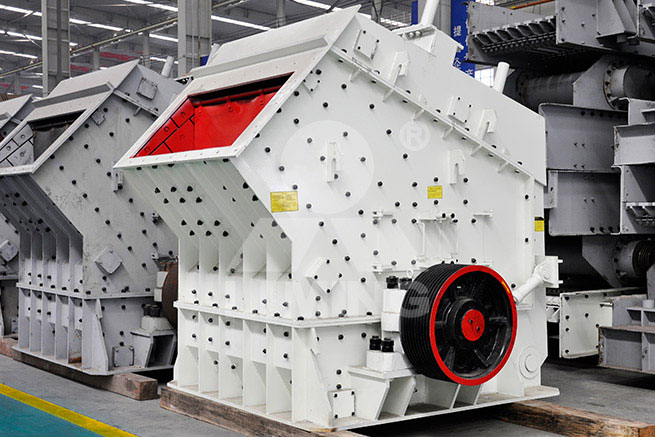

Impact crusher can crush what diameter stone

Impact crusher is not unfamiliar to everyone, in the stone processing plant, construction sites and grinding production line can be seen, but the impact crusher in the end can crush how big the diameter of the stone? In the use of each piece of equipment in the description of the introduction has been introduced, but for customers who have not been in contact with it seems to be not so clear, because in the mining equipment, as much as for the stone crushing equipment used in a lot of equipment, such as jawbreaker, hammer, impact broken, etc., and they can not even distinguish between the various types of crushing equipment in the end how the structure of what each has its own advantages and disadvantages, so today, OCP editorial from the beginning of the impact stone crusher for you to categorize! Explain each impact crusher.

Impact crusher details

Impact crusher model: PF-1007, PF-1010, PF-1210, PF-1214, PF-1315.

Maximum processing size: 60-450mm hard stone.

Processing capacity: 40-260t/h.

Component Function: The plate hammer and impact plate are the main crushing parts and wear parts, in which the impact plate consists of multiple impact fast, under the high-speed impact of the plate hammer and the rebound effect of the impact plate, the material realizes the crushing of iron to stone, stone to iron, stone to stone, due to the three-stage crushing cavity within the impact breaker, so the material can be crushed through the three-stage layer deep crushing effect, and finally in the adjusting device to realize the material screening, and the qualified material comes out. The qualified materials will come out.

From the above we can clearly understand the main information parameters of the impact stone breaker, the maximum handling stone diameter is very important technical standards, any material feeding size must be less than the maximum feed size, otherwise there will be feeding mouth jamming, plate hammer, impact plate and other wear and tear is too fast, the machine running noise and vibration and other phenomena, strictly speaking, less than 300mm stone can be crushed directly, more than 300mm will need to be based on the equipment to achieve the effect of screening, qualified materials out. 300mm or more will need to be determined according to the model of the equipment, that is, the larger the model can be crushed material size is also larger, for example, PF-1210, PF-1214 maximum feed size of 350mm, PF-1315 maximum feed size of 450mm. as for the discharge size, it is also necessary to consider the impact crusher crushing ratio of the problem, the finished product is usually less than 30mm 80%, that is, the crushing ratio is equal to 10:1, the more the crushing ratio is equal to 10:1, the crushing ratio is equal to 10:1, the crushing ratio is equal to 10:1, the crushing ratio is equal to 10:1. That is, the crushing ratio is more equal to 10:1, the specific particle size requirements can be controlled by adjusting the device, in addition, the finished material can be equipped with corresponding performance of the vibrating screen to screen out suitable materials.

As for the specific price of the equipment, you can always click on the website customer service consulting to get a favorable offer, we will arrange a person to receive you for a site visit.

-

How to control and regulate the feeding of Raymond mill inlet

-

On the mill production environment in the importance of stone powder grinding process

-

Power plant desulfurization can choose which kind of grinding mill

-

325 mesh desulfurization lime powder 15 tons per hour output choose which kind of grinding machine