How to customise the crushing production line of the crushing plant

Sand and gravel aggregate is an important structural material in the construction industry, the capital construction needs to consume a lot of sand and gravel aggregate, many investors see the business opportunities in the sand and gravel industry, have wanted to enter the line to get a piece of the pie. At present, more and more crushing plants on the market, but there are still many users come to consult the production line of the crushing plant how to build? The following is an answer to this question.

What should be considered in the design of crushing production line?

Different users have different production requirements, sites, investment budgets and so on, the design of crushing production line will also be affected, so in the design of crushing production line, it is generally necessary to consider a variety of factors:

1. Investment budget: the budget is a very important factor, the amount of investment budget directly affects the quality of the equipment, the size of the crushing production line and so on;

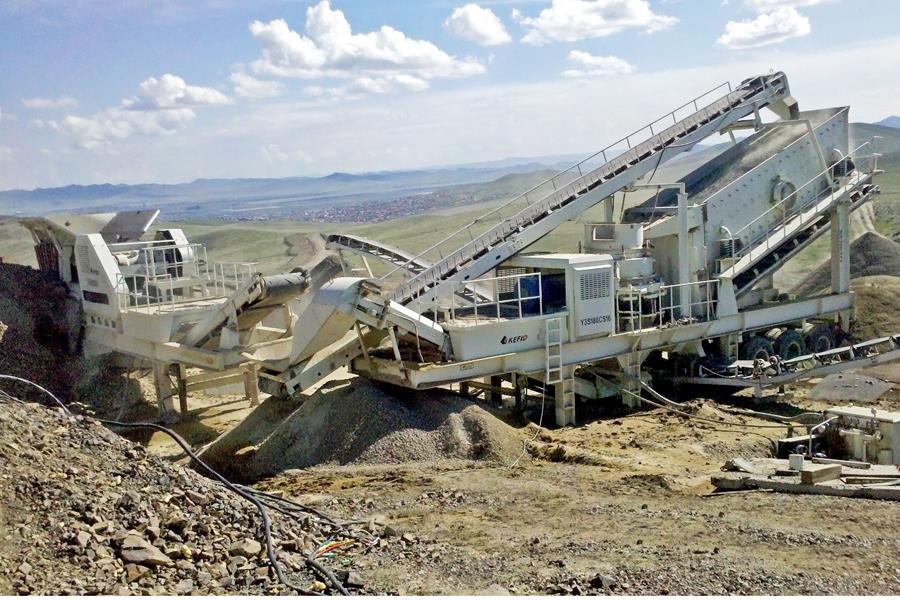

2. Site environment: when designing the crushing production line, the layout of the whole crushing production line should be taken into account in combination with the actual production site of the user, the equipment should be as compact as possible, and the principle of multi-stage crushing should be considered in the crushing process.

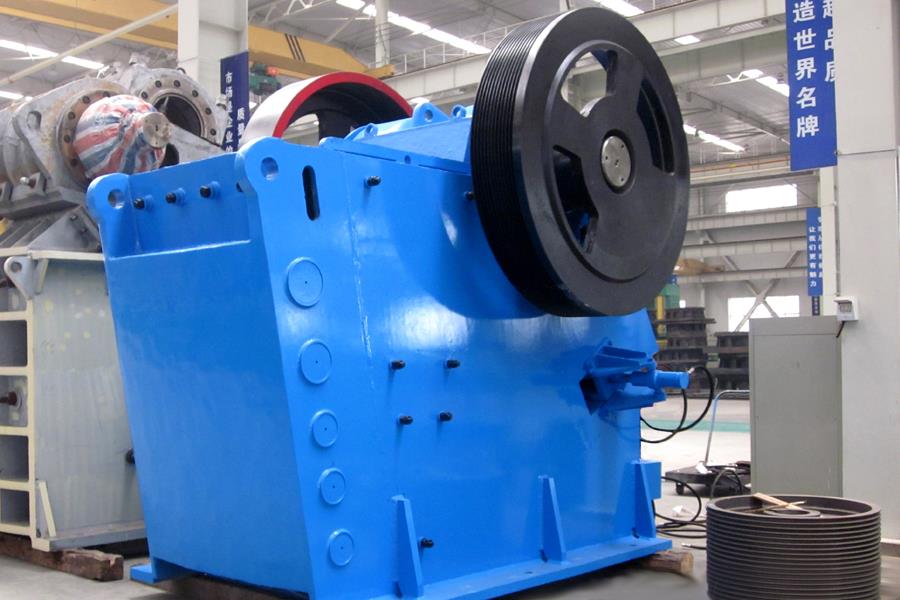

3. Crushing equipment: according to the nature of the raw materials, the requirements of the size of the incoming and outgoing materials, the production capacity to choose the appropriate equipment, and before and after the capacity of the equipment to match;

4. Feeding and screening equipment: the feeding equipment should meet the feeding requirements of the subsequent equipment to avoid jamming phenomenon, while the screening equipment try to choose a larger one, which can improve the output;

5. Environmental protection equipment: environmental protection in these years, green production has become the mainstream, the crushing production line will generally have noise, dust, sewage pollution, so in the design, should be equipped with relevant environmental protection equipment, help green production;

6. Finished product yard: design finished product yard, you can choose manual loading or automatic weighing and loading system;

7. Control system and monitoring system: centralised control, intelligent management and monitoring system should be designed to make the later operation and management of the crushing plant more convenient.

In addition to the above factors to be considered when designing crushing production line, the crushing production line should also follow the principles of multi-stage crushing, matching of front and rear stages of disposal, design of transit silo, matching of front and rear stages of material size, more screening and less crushing, more crushing and less milling, determining the belt according to the difference in output and transport height, and flexible layout of the site.

Welcome to click on the website customer service online consulting to get details and quotes, will be docked professional technical staff to provide you with detailed quotations, free tailor-made production line programme, and provide guidance on the procedures to run the plant, investment cost profit analysis, market analysis and other services.

-

1000tph crushed stone production line programme configuration details

-

What type of stone crushing machinery should be equipped with 300 tonnes per hour output