Environmental protection mechanism sand and gravel production line configuration programme recommendation

The development prospect of the mechanism sand industry is great, and more and more sand and gravel manufacturers have appeared on the market, but there are very many of them that are not standardised and do not meet the requirements of environmental protection, which cause great pollution to the environment. Sand and gravel manufacturers need an environmentally friendly mechanism sand and gravel production line, green production, energy saving and environmental protection.

Today we recommend this mechanism of gravel production line, indoor fully enclosed operation, green environmental protection, high degree of intelligence, the finished product has a good grain shape, is a mechanism of gravel production line with high comprehensive income. The main equipment is jaw crusher, cone crusher and sand making machine. The production line is composed of various equipment, a good production line can not be separated from the excellent performance of the equipment, so be careful when choosing equipment, according to the needs of the selection.

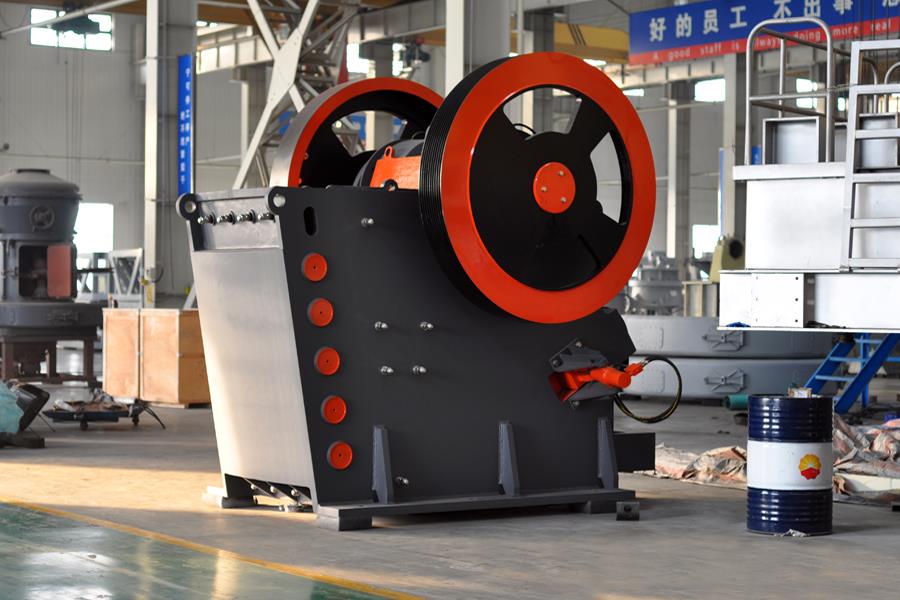

1. Jaw crusher: Jaw crusher is generally used for head crushing in mechanism sand and gravel production line, the feed and output are very large, the feed size is up to 1500mm, the hourly output of 1-2200 tonnes, suitable for coarse crushing of a variety of materials.

Advantageous features of jaw crusher:

The structure of the equipment is simple, solid, stable and reliable operation, and the operation and maintenance are also very convenient;

The crushing cavity is deep, the feeding capacity is strong, not easy to be blocked, and the output is also relatively large, with high efficiency and large crushing ratio;

The discharge port can be adjusted to change the size of the discharged material to meet different production requirements.

2. Cone crusher: Cone crusher is generally used in the mechanism of sand and gravel production line for secondary crushing, the hardness of the material for fine crushing, hourly output of 12-700 tonnes, mostly used in large-scale sand and gravel plant.

Advantageous features of cone crusher:

High degree of intelligence, remote touch screen control, stable and reliable operation of the equipment;

Hydraulic cavity cleaning system can quickly clean the crushing cavity, convenient and quick, reducing downtime and cost;

The wear parts are made of wear-resistant materials, which are not easy to be damaged and have a long service life, reducing the maintenance cost.

3. Sand making machine: sand making machine is fine crushing and sand making equipment in mechanism sand and gravel production line, which makes the material into sand and gravel with very fine granularity, which meets the standard of construction sand, with an hourly output of 12-650 tonnes.

Advantageous features of sand making machine:

Deep cavity impeller design, so that its throughput increased, ‘stone to iron’ crushing principle, high crushing efficiency;

Feeding mode and lubrication mode can be selected, flexible adjustment, convenient conversion, energy saving and environmental protection;

Combined with shaping function, the finished product has even grain shape and good appearance.

Configuration of a fully enclosed environmentally friendly mechanism of gravel production line needs several hundred thousand. If you want to configure a production line with a larger output and larger scale, the price will be higher, more millions. Different production needs, production line configuration programme will be different, the equipment required will be different, the price is naturally different, so it is recommended that users click on the online free consultation, or leave a message below your production needs, engineers will be based on your production needs to design environmentally friendly mechanism of sand and gravel production line programme, and provide you with a preferential offer.

-

How much is the price of small sand grinding machine equipment

-

Mobile crushing production line requires only one mobile crushing plant

-

How to configure 400 tonnes per hour stone crushing production line equipment