Can the steel slag from ironmaking be directly milled

Ironmaking out of the solid slag, there is called steel slag, also called water slag, in the past are used as paving slag, with the development of science and technology, in the field of cement and concrete, the use of steel slag micropowder can improve the performance of the concrete, play a greater value.

So can the steel slag from ironmaking be directly ground? The answer is no, because there is still some iron in the steel slag, if you can not separate these iron, not only a waste of iron resources, but also to the milling production difficulties, iron hardness is very high, grinding up the mill's loss is very large, resulting in a very low yield.

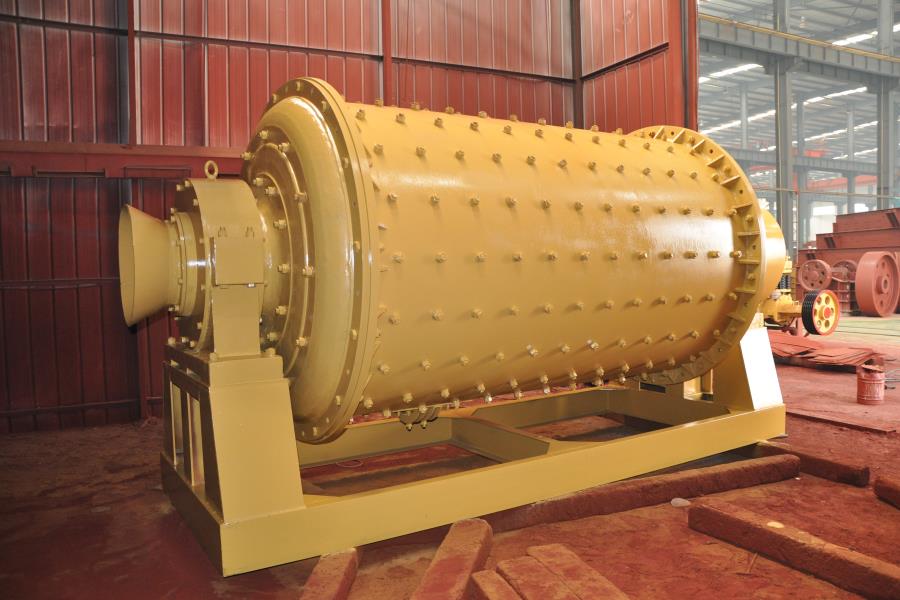

How good it is, here we have to use the iron selection process, the use of crusher and ball mill, the steel slag after crushing, and then use the magnetic separator, will be inside the high iron content particles are selected, the remaining slag is now concrete mixing plant used by the steel slag.

Selection of iron after the steel slag iron content is very small, and the particles are very small, can be directly into the mill, the purchase of our company's steel slag mill, can be ground to 325 mesh or even finer fineness, throughput rate of more than 90%, to meet the standard demand for slag powder mixing plant, now the large-scale high-pressure grinding mill, can reach a daily output of more than 500 tons, is one of the rare equipment. As for the specific price of the equipment, you can always click on the website customer service consulting to get a favorable offer, we will arrange for a person to receive you for a site visit. Click on the website customer service to consult immediately, 24 hours online.

-

The company launched a supporting program for power plant customers

-

How to connect the raymond mill discharge port and packaging machine

-

The difference between grinding silicon dioxide and silicon carbide

-

What are the advantages of Raymond mill in powder processing