Application of talcum powder mill with different fineness of finished product

Talc is a relatively common silicate mineral in nature, because of its good lubricity, fire resistance insulation, flow aids and other characteristics, is widely used in industry, agriculture, medicine and other industries, but due to the different application scope of talcum powder requirements vary greatly, the following we will be a more representative use of the case as an example, to briefly illustrate the quality of talc in the different uses of talcum powder quality requirements, and thus better judgement! What type of talcum powder mill model to choose.

Judging the quality of talcum powder, whiteness, fineness is an important criterion, talcum powder according to the fineness of the difference can be divided into two types of fine talcum powder and micro fine talcum powder, each type according to its whiteness, fineness ratio is divided into first-class, second-class, qualified products, etc., the specific requirements are as follows:

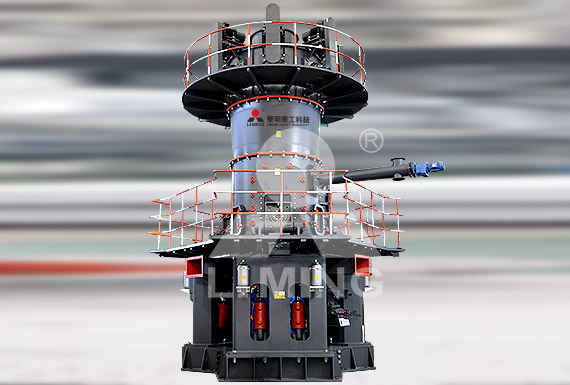

1. ultra-fine mill grinding out of talcum powder fineness uniform rank, fineness range between 500-800 mesh, applied to advanced paints and coatings, plastics, cosmetics, textile lubricants, medicine and other industries, which is most closely related to our lives to medicine, cosmetics, cosmetics used in most of the daily use of cosmetics contain a small amount of talcum powder, one is to increase the product's delicate lubrication, and the second is to whiten the whitening effect, and the other is to whiten the skin powder, prickly heat powder, and the other is to whiten the skin powder, and the other is the whitening effect, and the other is to whiten the skin powder. In addition, talcum powder, prickly heat powder are also more common, the main ingredient of which is also talcum powder, such applications most of the talcum powder requirements in the 800 mesh or so, in addition to ultra-fine mill, micro powder mill, three-ring medium-speed mill is also a good choice.

2. Powder other than micro fine talcum powder can be ground talcum powder, the dosage is larger, the use of a wider range, it can be said that the micro fine powder for special processes, while grinding fine powder for the public demand, such as papermaking, coatings, plastics, rubber, cables, waterproof materials, ceramics and so on.

3. Paper-making process: whiteness of 88% or more for qualified products, 92% for first-class products, fineness requirements of 325 mesh, as paper, cardboard filler, can also be used as a wood asphalt control agent, mill selection Raymond mill can be.

4. Wall coating: fineness requirements are higher, whiteness is slightly loose, used as white body pigment and to give the class of water-based, oil-based, resin coatings and paint additives fineness of more than 800 mesh, whiteness of 70% is qualified, the general industrial mill can not meet the fineness requirements, need to choose micro-fine powder mill processing, that is, the same as the above micro-fine powder mill selection.

5. Plastics, rubber, cable manufacturing: the above three processes of talcum powder fineness requirements are generally the same, are 325 mesh, the difference is that the plastic material on the whiteness of talcum powder also has obvious provisions, 88% is qualified, 95% for the first grade, Raymond mill, high-pressure mill, European version of the mill can be used as a supporting grinding equipment for the three manufacturing processes.

6. Ceramic process: talcum powder in the high temperature calcination whiteness enhancement, good luster, and smooth and delicate surface, is the main raw material for electric porcelain, ceramics, porcelain glaze, etc., the whiteness requirement of 88% or more, fineness of 325 mesh.

7. Waterproof materials: waterproofing roll-roofing materials on the market, waterproof coatings, waterproof ointment in the application of talcum powder is more, whiteness, fineness requirements are not high, ordinary ore mill can meet the ideal requirements, the fineness and flour is similar to the 200 mesh or so, the general raymond machine can easily complete the grinding task.

From the above can be, different applications talcum powder fineness and whiteness requirements are different, so the choice of mill is not the same, different kinds of talcum powder mill regardless of price, performance, life expectancy and other differences, here also remind you of the choice of equipment is not to listen to the words of others, and simply think that other people processing talcum powder to choose such a mill can be used by yourself, the same premise in the material, the actual Under the same premise, the actual use of the material is the key to the final decision of equipment selection.

As for the specific price of the equipment, you can always click on the website customer service consulting to get a favorable offer, we will arrange for a person to receive you for a site visit.

-

Talc raymond mill greatly improve the effect of oily wastewater treatment

-

How to choose the right type of grinding mill to produce high quality mineral powder

-

Benefits of waste glass recycling and glass crusher selection supporting the analysis of the problem

-

Raymond mill led industrial waste into the foam glass new materials market